Product Knowdge

Material & coating selection that matters for soup bowls

Choosing the proper paperboard grade and food-contact coating is the most practical decision a buyer makes. For high-temperature soups you want a heavier base paperboard (typically 200–350 g/m²) to resist sag and to give a secure feel in-hand; lighter board saves cost but shows indentation and becomes floppy. Coating options determine grease and leak resistance: polyethylene (PE) is the industry workhorse — inexpensive and excellent for short-term hot liquid containment. Bioplastic coatings such as PLA provide compostability in industrial facilities but have lower steam-barrier performance at very high temperatures. Specialty multi-layer coatings (for example a thin EVOH barrier laminated between layers) can boost oxygen and aroma retention for broths with long hold times.

Practical takeaways

- For delivery of hot soups keep board at or above 250 g/m² to avoid bottom sag during handling.

- PE coatings are reliable for short-term hot liquid use; request a heat-age test to confirm no seepage at your intended holding temperature.

- If compostability is a selling point, specify compostable certification (EN 13432 or ASTM D6400) and verify municipal or industrial compost acceptance — not all regions accept coated paper products.

Design features that improve stackability, handling and delivery

A soup paper bowl's geometry directly impacts logistics and end-user experience. A tapered wall profile eases nested stacking, reducing transport volume. Reinforced rolled rims increase lid retention force and create a secure leak-resistant mating surface. At the base, a slightly raised ring or thicker floor layer prevents centrifugal indent when a courier places multiple orders on a tray — this small change reduces puncture and deformation during transit. When designing for high-temperature soups, avoid ultra-thin bases even if the sides are thick; the bottom takes the full weight load of liquid and additives (noodles, chunks, toppings).

Checklist for specifications

- Specify rim OD and lid model to guarantee a tight fit and consistent leak performance.

- Indicate maximum fill temperature and expected hold time so factories can validate coatings and seam sealing.

- Request a sample run and shipping simulation (vibration, stacking pressure) for large orders.

Manufacturing controls and quality tests to insist on

Robust QC prevents downstream returns. Key process controls include basis weight verification, coating weight uniformity, heat-sealing strength, and side-seam integrity. Common tests that yield actionable results: water immersion/leak test (short duration), hot fill leakage (simulate actual product temperature), hot-board flex test (measure deflection under standard weight at temperature), and grease resistance (KIT TEST). Also require periodic microbiological swabs for food-contact tooling if the production environment handles wet food processes.

Suggested test parameters

| Test |

Condition |

Acceptance goal |

| Hot fill leak |

95–100°C, 15 min |

No seepage or seam failure |

| Board flex |

Load 500 g at center, 60°C |

Deflection < 5 mm |

| Grease resistance |

TAPPI or kit test |

Rating ≥ 8 |

Heat retention and insulation: physics you can use

Heat loss from a soup paper bowls occurs via conduction (through the paper and lid), convection (air movement at the rim) and radiation. Thicker paperboard with a proper air gap or corrugated layer reduces conductive losses; coatings should be thin enough to avoid adding thermal bridges but thick enough to prevent liquid migration. A tightly fitting lid reduces convective losses dramatically — every millimeter of rim seal improves retention. In practice, pairing a 250–300 g/m² single-layer bowl with an insulated lid can extend usable hot hold time by 20–45% over an open bowl, depending on ambient conditions.

Practical packing tips to maximize temperature on delivery

- Use insulated carrier bags and place bowls upright with lids fastened; lateral pressure can cause seam leakage.

- Avoid stacking warm bowls directly on each other — leave a thin cardboard separator to reduce conductive heat transfer between items, which preserves temperature distribution.

- If shipping cold chain items together, package hot bowls separately to prevent condensation and weakening of coatings.

Sustainability, end-of-life and regulatory considerations

Sustainability claims must be evidence-based. Compostable coatings require certification and appropriate waste infrastructure; otherwise a 'compostable' bowl may end up in landfill where biodegradation is slow. Recyclability is limited when PE coatings are used — some regions accept PE-coated paper in pulping streams, others do not. When choosing materials, check local municipal guidelines, request chain-of-custody certificates for virgin or recycled fiber, and consider offset options. Also ensure all food-contact coatings comply with relevant local regulations (for example, FDA or EU food contact laws) and obtain migration test reports if the product will contact acidic soups or high oil content broths.

Supplier selection tips

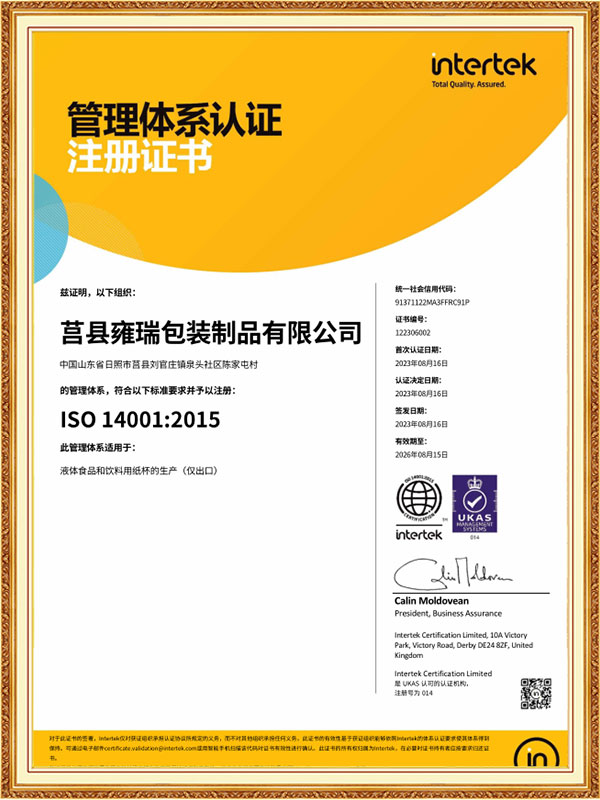

- Ask for COAs (Certificates of Analysis) for fiber content and coating composition.

- Audit the production base for capacity and line flexibility — large bases with flexible lines reduce lead time risk for promotions and seasonal spikes.

- Request a small production run with full testing before committing to a large-volume order; a trusted partner will support iteration quickly.

I take pride in fast iteration and stable supply — when you need consistent quality at scale, we can adjust lines and deliver validated samples rapidly. If you want, I can walk you through specification language to include in purchase orders so the manufacturer delivers precisely what you need.

+86-18863350588

+86-18863350588

English

English Français

Français Deutsch

Deutsch Español

Español