Product Knowledge

Material choices and performance trade-offs

Paper bowls for ice cream are no longer a single-material solution; modern manufacturing blends base paper grade, wet-strength fibers, and functional coatings. Higher grammage papers (270–350 gsm) provide structural rigidity for multi-scoop servings, while specialized wet-strength additives keep seams intact when exposed to melting. For premium applications we often specify a bleached kraft base with a clay-coated printable surface to get vivid colors without sacrificing stiffness — and we can scale those runs to meet seasonal spikes with reliable lead times.

Coatings: what they do and when to use them

Coatings control liquid resistance, grease resistance, and thermal conduction. The three most common approaches are aqueous barrier coatings, polyethylene (PE) lamination, and bio-based barrier coatings (PLA or PHA). Each has distinct manufacturing, recycling, and cost implications that affect both performance and the downstream waste stream.

- Aqueous barrier coatings — good for printability and recyclable with paper recycling streams when applied in thin layers; moderate moisture resistance.

- PE lamination — excellent waterproofing and grease protection; increases moisture barrier but complicates paper recycling unless separated at end-of-life.

- PLA/PHA bio-coatings — compostable in industrial facilities and visually similar to PE; require clear labeling to avoid contamination in mixed recycling systems.

Design geometry tuned for scoops and ergonomics

Optimizing internal curvature and rim profile significantly improves consumer handling and presentation. A slightly flared rim (4–8°) makes scoops sit cleanly while an internal radius of 6–8 mm reduces stress concentrations where cracks can start. We tailor wall thickness and bead-rolled rims to improve hand grip and reduce deformation from thermal shock when the cold product contacts a warmer hand.

Practical tips for tooling and run-up

Tooling tolerances should be specified to ±0.3 mm for diameters and ±0.5 mm for height on high-volume runs to maintain stackability and dispenser compatibility. Progressive die adjustments during the first production batch reduce scrap—we routinely set up pilot runs to validate tooling geometry before full-scale production.

Thermal behavior and cold retention strategies

Paper alone is a poor insulator compared with foam, so manufacturers rely on multi-layer construction and surface texture to slow heat transfer. Air gaps created by double-wall constructions and micro-embossing on the exterior increase thermal resistance without adding significant material weight. For take-home or delivery use cases, pairing a thicker wall with an insulating sleeve or a sealed lid yields measurable retention of texture and melt rate.

When to use single-wall vs. double-wall

Single-wall ice cream paper bowl are lighter and economical for immediate consumption; double-wall designs are justified when delivery, extended consumption time, or multi-scoop premium presentations are required. I recommend double-wall for sundae-style sales or any SKU intended for travel — we can produce both efficiently on adjacent lines.

Printing and surface effects that sell in-store

High-impact visuals drive impulse buying. Techniques like UV printing, spot gloss varnish, and cold-foil accents make colors pop on clay-coated stock. Halftone control and dot gain compensation are essential for consistent brand color across batches; plates should be proofed on the actual stock plus coating rather than on proofing paper to avoid surprises.

- Use expanded gamut or CMYK+Orange for saturated fruit tones often used in ice cream imagery.

- Apply tactile varnish selectively on logos or flavor icons to create a premium perceived texture with minimal added cost.

Sustainability and end-of-life concerns

Sustainability choices must balance collection infrastructure, product safety, and branding. Choosing recyclable aqueous coatings can enable paper-stream recycling in many municipalities, while compostable coatings require clear certification and consumer guidance. Life-cycle impacts should be evaluated across raw materials, manufacturing energy, transport weight, and disposal.

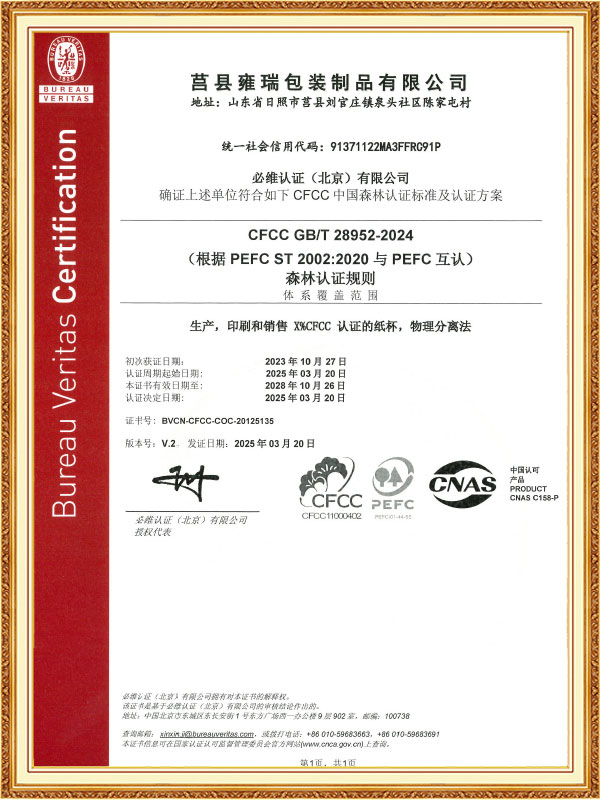

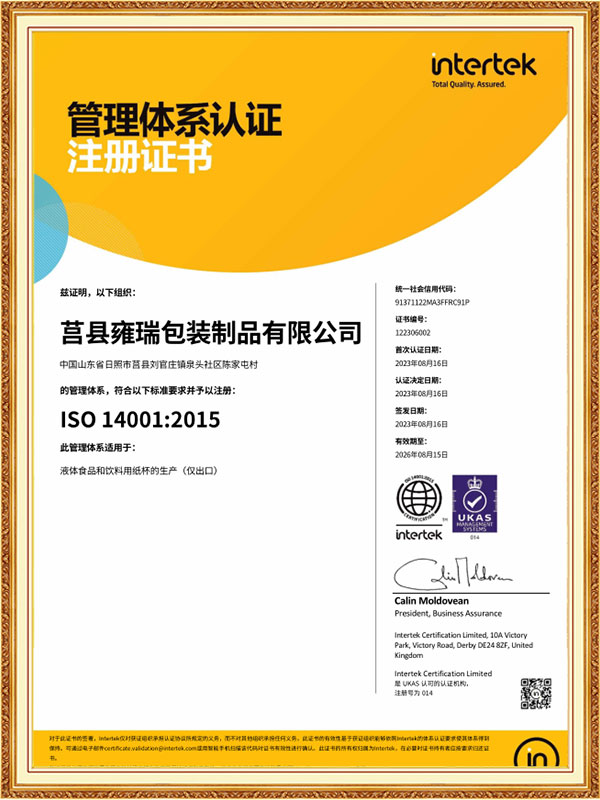

Labeling and certification best practices

Always display clear end-of-life guidance on the cup (e.g., “Recycle where facilities exist” or “Industrial composting only”) and, where applicable, include certification logos (e.g., FSC, OK compost INDUSTRIAL). Mislabeling leads to contamination or rejected streams; we verify label placement during prepress checks to avoid costly recalls.

Quality control, testing, and regulatory checks

Critical tests include water soak, seam burst, grease resistance, and migration testing for coatings in contact with fatty food matrices. For export markets, check local food-contact regulations (e.g., overall migration limits). We maintain a QC protocol that samples batches for dimensional tolerances, coating integrity, and print color consistency to ensure each roll meets customer expectations.

| Barrier Type |

Moisture Resistance |

Recycling Impact |

Best Use |

| Aqueous Coating |

Moderate |

Favorable where accepted |

In-store single-serve |

| PE Lamination |

High |

Challenging (mixed stream) |

Delivery or long-dwell products |

| PLA/PHA |

High |

Compostable (industrial) |

Eco-marketed premium lines |

Logistics, packaging, and shelf-life considerations

Stacking strength, pallet configuration, and humidity control in storage influence damage rates. For long-distance shipments we recommend interleaving sheets and using edge protectors to avoid rim deformation. Ambient storage should be kept below 35% relative humidity to prevent curl and maintain adhesive performance in glued seams.

Enhancing end-consumer experience

Small design choices increase perceived value: a matt varnish that reduces glare for social-media-friendly photos, a ruled interior for portion guidance, or a notch for spoon rest. Subtle tactile cues and stable base profiles reduce spillage and improve eating comfort. We're proud to work with clients to integrate these small but high-impact details into run-ready dielines.

+86-18863350588

+86-18863350588

English

English Français

Français Deutsch

Deutsch Español

Español