Product Knowledge

Ripple Wall Paper Cup Design and Benefits

Ripple wall paper cups are designed with a unique textured exterior that enhances grip and insulation. This texture not only prevents slipping but also helps maintain the beverage temperature for longer periods. In our experience at Yongrui, pairing these cups with tight-fitting lids ensures consumers can enjoy their hot drinks safely on the move, whether commuting or traveling.

Precision Quality Control in Paper Cups

Quality assurance is crucial for disposable cups, especially when handling hot liquids. At Yongrui, we implement a rigorous 4-step quality inspection process that ensures the leakage rate is maintained below 0.0001%. This meticulous process covers material selection, wall integrity, lid fit, and final stress testing. Our clients can rely on this system to maintain consistent safety and performance in large-volume orders.

Material Considerations for Hot Beverages

When selecting materials for paper cups, the combination of food-grade paper and biodegradable coatings is essential. Ripple wall paper cups utilize high-density paperboard that resists deformation under heat, while our internal coating ensures the liquid remains uncontaminated. From my perspective, having a robust production base allows us to test and iterate these materials rapidly, ensuring a premium feel and performance every time.

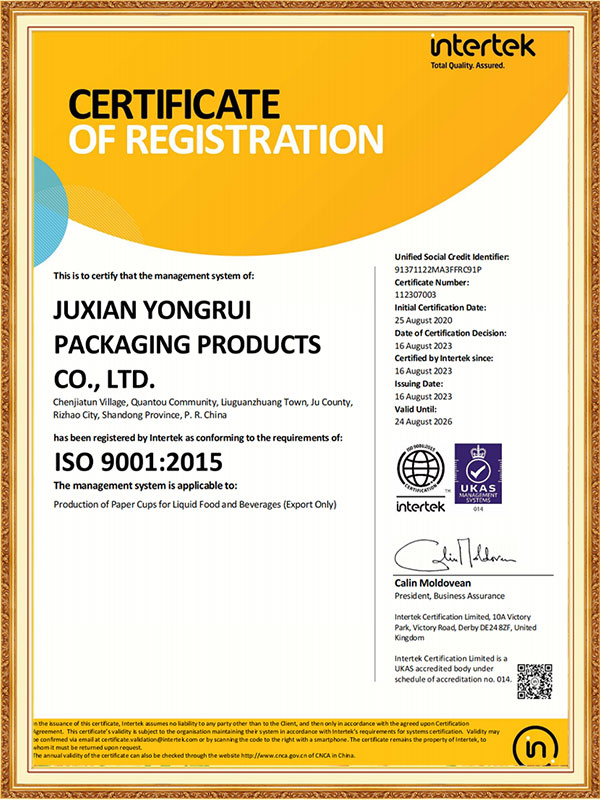

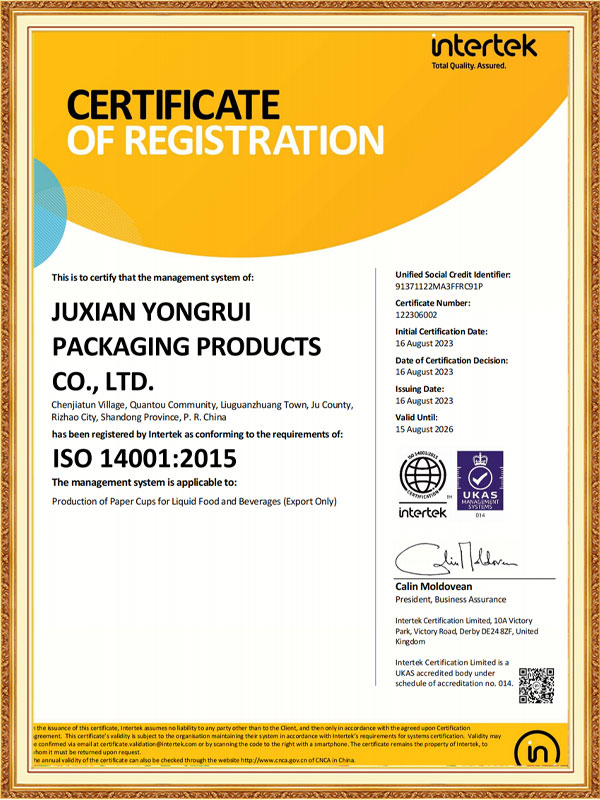

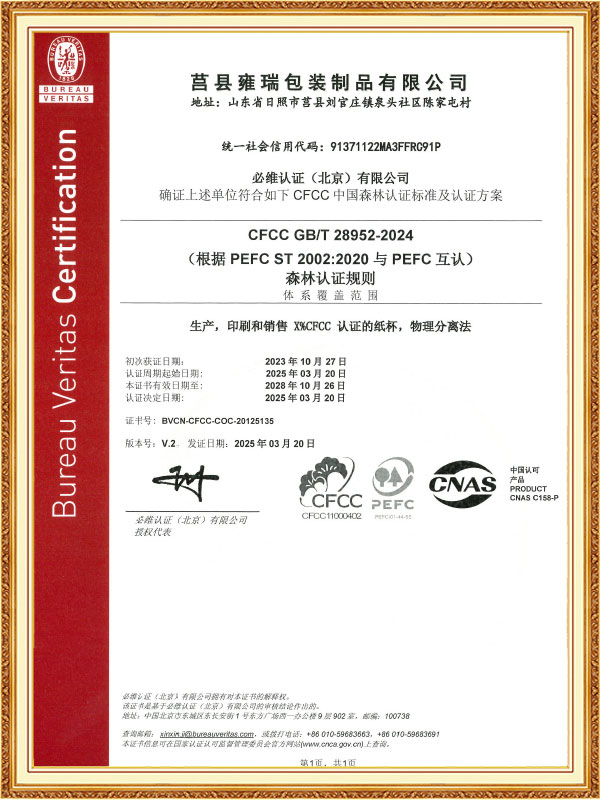

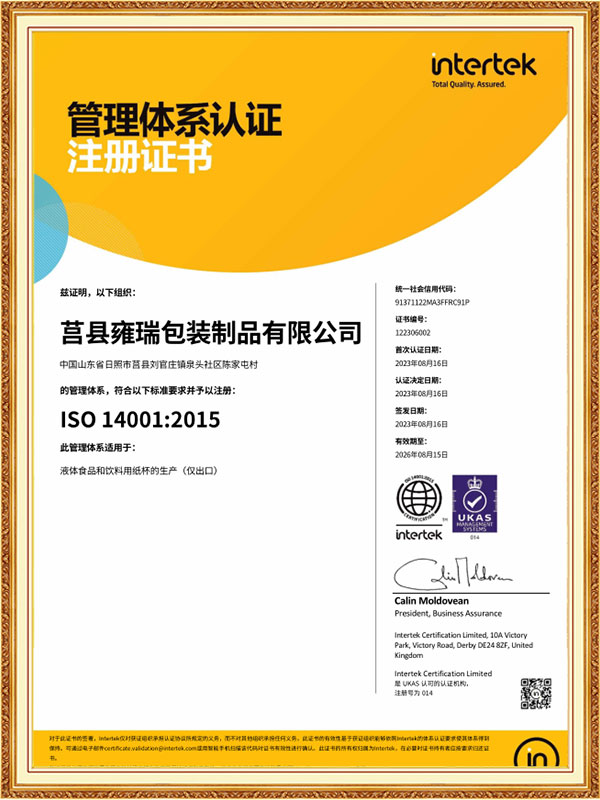

Global Certification Standards

International certification is often a decisive factor for companies looking to scale globally. Our ripple wall paper cups have obtained multiple certifications, including FDA, LFGB, and FSC, supporting diverse market entry requirements. Each certification reflects our commitment to quality, safety, and environmental responsibility.

Key Certification Benefits

- Ensures compliance with international food safety standards.

- Facilitates smoother customs and import procedures.

- Enhances brand trust when marketing to overseas consumers.

- Demonstrates commitment to sustainable and ethical sourcing.

Optimizing Production for Large Orders

Managing large-volume orders requires flexible production lines and efficient logistics. Our production base at Yongrui is structured to allow rapid adjustments in line speed, coating application, and packaging methods. This ensures that even custom orders maintain high quality without delaying delivery schedules.

Production Efficiency Table

| Production Step |

Average Duration |

Quality Check |

| Paperboard Forming |

2 minutes per cup |

Thickness & Flexibility |

| Ripple Texturing |

1.5 minutes per cup |

Grip & Insulation Test |

| Lid Fitting |

1 minute per cup |

Leakage & Seal Test |

| Final Inspection |

0.5 minutes per cup |

Overall Appearance & Compliance |

+86-18863350588

+86-18863350588

English

English Français

Français Deutsch

Deutsch Español

Español