Product Knowledge

Understanding the Role of PLA in Sustainable Packaging

Polylactic Acid (PLA) is a biodegradable polymer derived from renewable resources such as corn starch or sugarcane. Unlike petroleum-based plastics, PLA decomposes under industrial composting conditions, significantly reducing environmental impact. In the paper cup industry, PLA coatings replace traditional PE coatings, offering compostable solutions without compromising product durability. At Yongrui, we integrate this material into our high-standard production system, ensuring eco-friendly products that align with modern sustainability goals.

Thermal Stability and Performance in PLA-Coated Paper Cups

One key aspect of PLA paper cups is their thermal resistance. PLA coatings typically perform well with hot beverages up to around 80°C. To enhance heat resistance, manufacturers may apply multi-layer coatings or blend PLA with other bio-based polymers. Our flexible production lines allow us to adjust these formulations efficiently, ensuring each batch maintains consistency while meeting specific temperature requirements.

Flexo Printing Applications in PLA Paper Cups

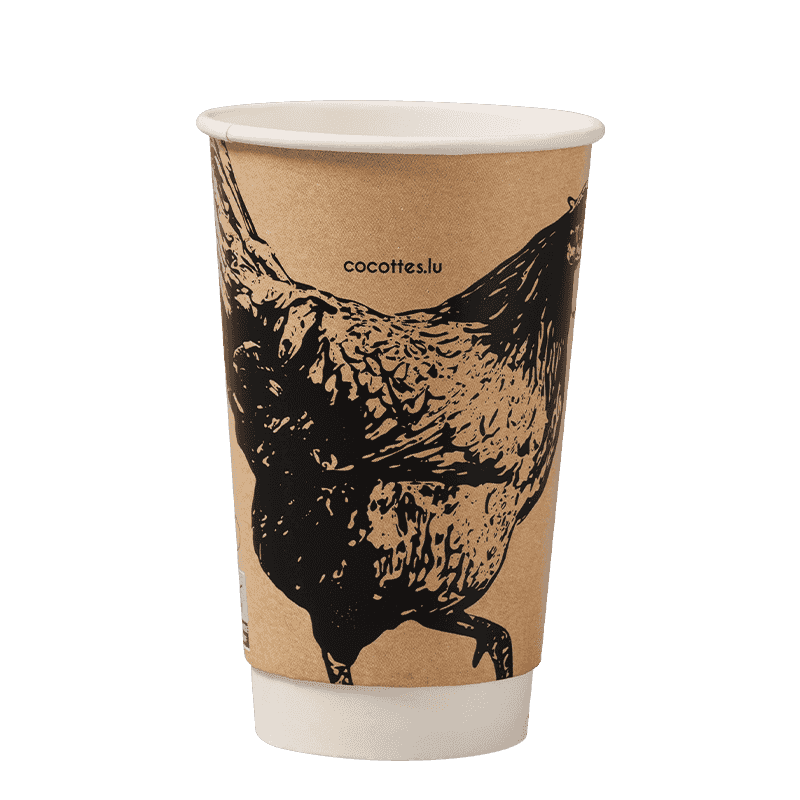

Flexographic printing is particularly well-suited for PLA-coated paper surfaces. Using water-based inks, this printing technique ensures high color fidelity while maintaining environmental compliance. Yongrui offers 1–9 color flexo printing options, enabling vibrant branding without affecting compostability. Our large-scale production capacity supports quick turnaround and design iteration—ideal for businesses that update their visual identity frequently.

Comparative Overview: PLA vs. Traditional PE Coating

| Feature |

PLA Coating |

PE Coating |

| Base Material |

Corn or sugarcane |

Petroleum-based |

| Compostability |

Industrial compostable |

Non-compostable |

| Heat Resistance |

Up to 80°C (modifiable) |

Up to 90°C |

| Environmental Impact |

Low, renewable source |

High, fossil-based |

Storage and Handling Tips for PLA Paper Cups

While PLA-coated paper cups are durable under normal conditions, they should be stored away from direct sunlight and high humidity. Long exposure to heat may cause deformation or stickiness, as PLA is sensitive to temperature changes. We recommend keeping products in a well-ventilated warehouse below 40°C. With our efficient logistics and large-scale facilities, we maintain strict environmental controls to deliver cups that retain optimal performance upon arrival.

Innovative Trends in PLA Paper Cup Development

Recent innovations focus on improving the crystallinity of PLA for enhanced durability, developing hybrid bio-coatings, and advancing printing techniques for higher precision. Some manufacturers explore blending PLA with natural fibers for added strength. At Yongrui, our rapid product iteration cycle enables us to test and adopt such technologies swiftly, ensuring our customers always receive forward-thinking, reliable solutions that keep pace with market evolution.

Practical Applications in Food and Beverage Operations

PLA paper cups are gaining traction in cafes, restaurants, and catering services that value eco-conscious branding. They perform exceptionally well with cold drinks and moderately hot beverages, maintaining structure and print quality even during extended use. Some businesses pair PLA cups with compostable lids and sleeves to create a fully sustainable packaging system. Our production versatility ensures custom sizing and branding to meet diverse operational requirements without sacrificing speed or quality.

End-of-Life Management and Recycling Compatibility

Though PLA is compostable, it requires industrial composting facilities to fully decompose. In regions lacking such infrastructure, proper waste sorting becomes essential. Educating end users about disposal options can improve sustainability outcomes. We often collaborate with partners who promote eco-friendly waste systems, ensuring our PLA paper cups contribute to a circular economy wherever possible.

Key Considerations for Businesses

- Verify local composting or recycling options before large-scale adoption.

- Select appropriate coating thickness based on intended beverage type.

- Ensure printing inks are compliant with food-contact standards.

- Work with manufacturers offering flexible customization and stable supply—like we do at Yongrui.

+86-18863350588

+86-18863350588

English

English Français

Français Deutsch

Deutsch Español

Español