Product Knowledge

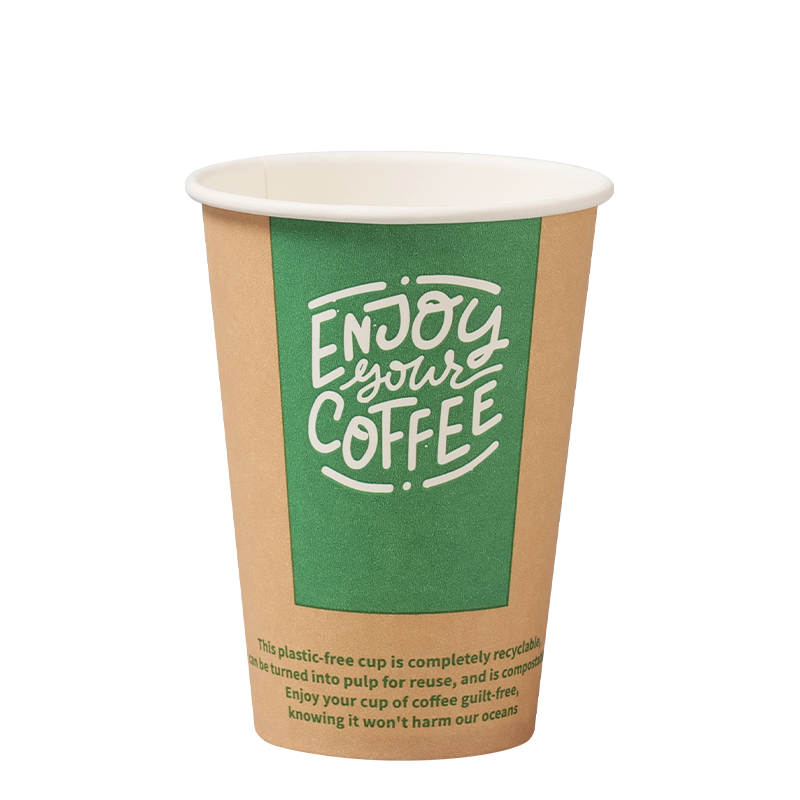

Environmental Advantages of Aqueous Paper Cups

Aqueous coating paper cups significantly reduce plastic usage compared to traditional PE or PLA-coated cups. In some formulations, plastic content can be as low as 3%. By using these cups, businesses can lower their environmental footprint without compromising the functionality of their beverage packaging.

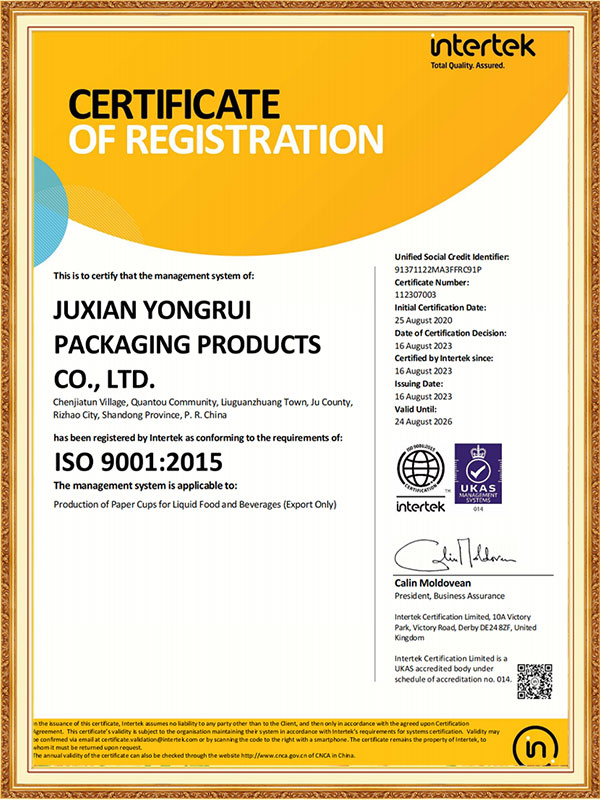

At Yongrui, we take pride in supplying these cups efficiently, ensuring that your eco-friendly transition is seamless and well-supported by a reliable production base.

Thermal Performance for Hot and Cold Beverages

Aqueous paper cups provide excellent insulation, making them suitable for both hot and cold drinks. Their structural integrity remains intact even under high temperatures, reducing the risk of leaks or deformation that can occur with thinner plastic-coated cups.

- Hot beverages: Retain heat longer while remaining safe to hold

- Cold beverages: Minimize condensation and maintain cup strength

- Multi-layer stability: Ensures cups do not warp under extreme temperatures

I can confidently say that our flexible production lines allow us to produce cups with consistent thermal performance, meeting diverse client requirements efficiently.

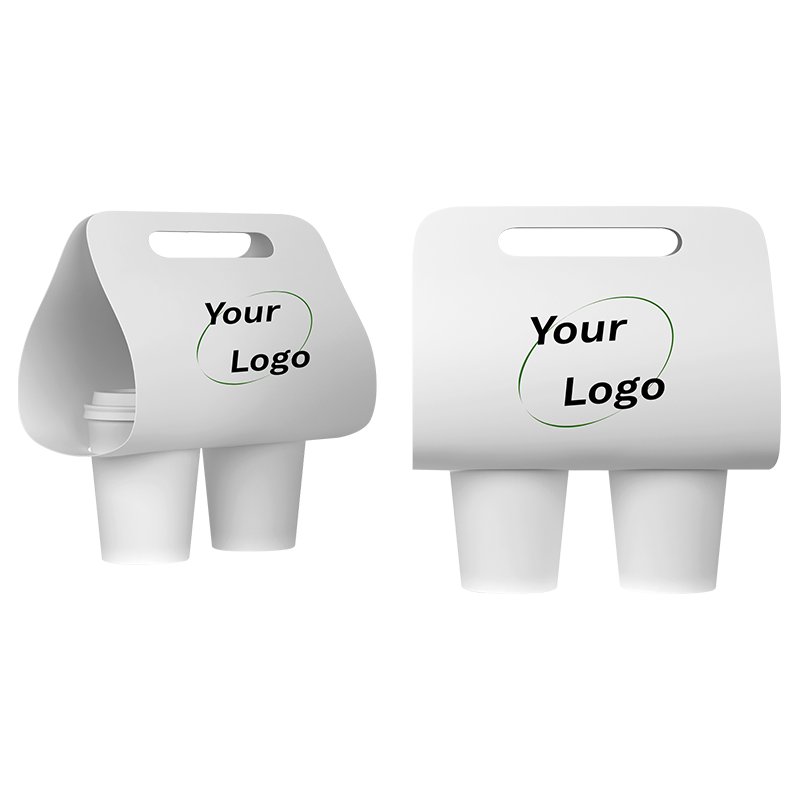

Production Flexibility and Supply Chain Reliability

Yongrui's large-scale production base allows us to handle both high-volume orders and small-batch custom requests. This flexibility ensures that any adjustments in product specifications or design changes can be accommodated quickly.

Reliable supply chain management means our clients never have to worry about production delays, even during peak demand periods.

| Production Volume |

Flexible from 10,000 to 1,000,000 units per order |

| Customization |

Available for size, print, and coating thickness |

| Lead Time |

Rapid production cycles with consistent quality |

Optimizing Aqueous Coating Formulations

The effectiveness of aqueous coatings depends on formulation precision. By controlling coating thickness and curing processes, aqueous coating paper cups can achieve high liquid resistance while minimizing plastic content. Some best practices include:

- Ensuring uniform coating to prevent weak points in the cup wall

- Using water-based adhesives to improve recyclability

- Testing cups under various temperature conditions for optimal performance

With our advanced production setup, I can ensure that each batch meets these high standards, providing you with environmentally responsible and high-performing cups.

+86-18863350588

+86-18863350588

English

English Français

Français Deutsch

Deutsch Español

Español