Industry Knowledge

Sustainability Trends in Single Wall Paper Cups

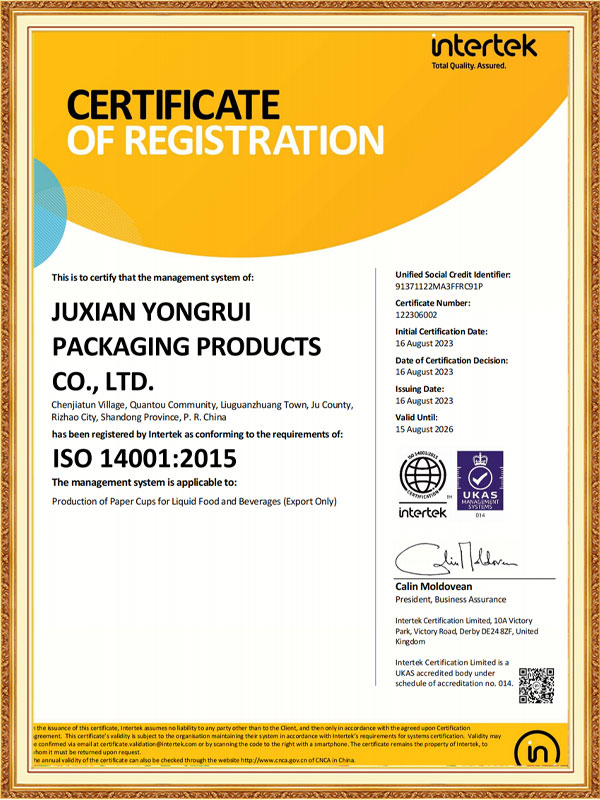

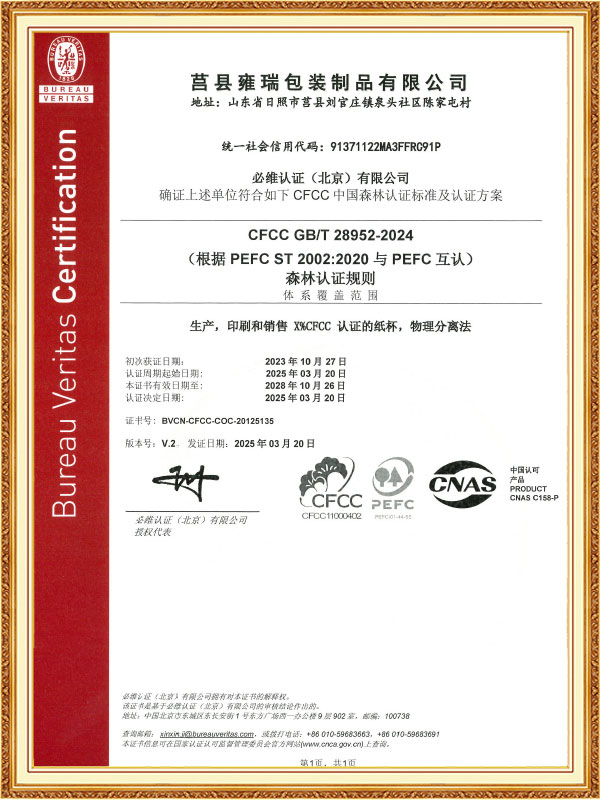

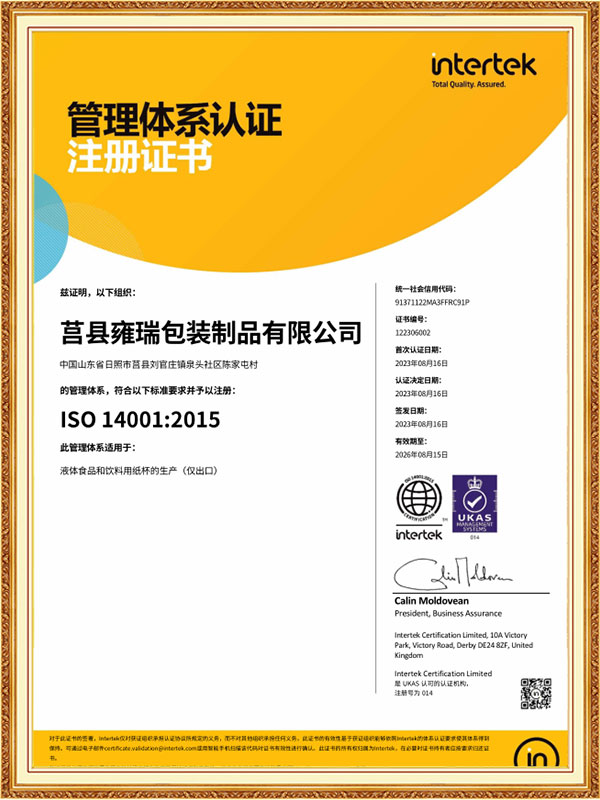

The industry is seeing rapid adoption of eco-friendly coatings and biodegradable linings for single wall paper cups. Unlike traditional PE coatings, new water-based and PLA solutions make cups fully compostable while maintaining durability. As a manufacturer with a flexible production base, we can quickly adjust our lines to support these sustainable materials, helping brands stay compliant with evolving environmental standards.

Optimizing Cup Design for Brand Visibility

Effective cup design goes beyond aesthetics—color contrast, logo placement, and surface texture directly influence consumer perception. Single wall paper cups provide an excellent canvas for high-resolution printing, especially with UV and flexographic techniques. We often collaborate with clients to test print precision and coating compatibility, ensuring the final product reflects their brand identity without compromising quality.

Temperature Retention and Material Engineering

Although single wall cups are typically used for cold or moderate-temperature beverages, material optimization can enhance thermal performance. Techniques such as micro-embossing or inner lamination improve insulation while keeping the cup lightweight. Our production team continuously experiments with these engineering improvements, achieving stable performance across large batches.

Supply Chain Stability and Bulk Customization

For businesses operating at scale, stable supply and customization flexibility are crucial. Bulk orders of single wall paper cups require synchronized material sourcing, printing accuracy, and packaging logistics. At Yongrui Packaging, our extensive production base allows us to maintain both speed and precision during high-volume runs—ensuring reliable delivery even during seasonal demand spikes.

Common Coating and Lining Options

| Coating Type |

Description |

Advantages |

| PE Coating |

Traditional plastic lining for moisture resistance |

Cost-effective and widely available |

| PLA Coating |

Biodegradable material derived from plant starch |

Eco-friendly and compostable |

| Water-Based Coating |

New-generation sustainable barrier technology |

Excellent recyclability and safe for direct food contact |

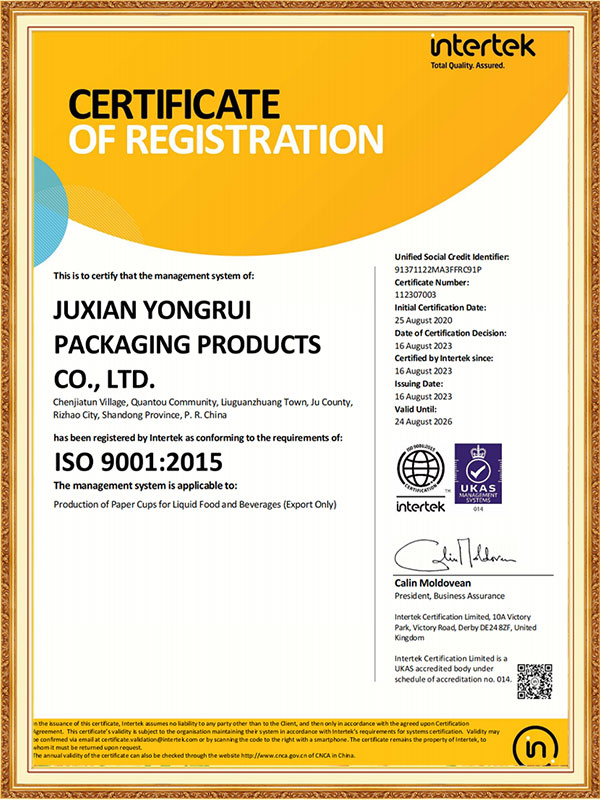

Quality Control During High-Speed Production

Maintaining consistency in rim rolling, sealing, and printing alignment is a challenge during high-speed manufacturing. We employ automated inspection systems that detect even slight deviations in color or shape. This attention to detail ensures every batch of single wall paper cups meets strict quality benchmarks, reinforcing long-term brand trust.

Practical Storage and Handling Guidelines

Proper storage significantly affects the longevity of single wall paper cups. Exposure to humidity or direct sunlight can weaken the structure and fade print colors. To maintain product integrity:

- Store cups in a dry, well-ventilated environment.

- Avoid stacking beyond recommended height to prevent deformation.

- Rotate inventory regularly to ensure freshness of print and material quality.

Emerging Printing Technologies for Paper Cups

Recent innovations in digital printing allow for short-run customization and faster turnaround times without compromising ink adhesion or color depth. This is particularly valuable for promotional or seasonal designs. With our rapid iteration capabilities, we can help clients test new layouts and visual concepts almost in real-time.

+86-18863350588

+86-18863350588

English

English Français

Français Deutsch

Deutsch Español

Español