Industry Knowledge

Thermal Insulation Techniques in Disposable Paper Cups

Effective insulation is one of the most crucial aspects in the design of disposable paper cups, especially for hot beverages. While double-wall paper cups are common, newer innovations include air gap layers and advanced coatings that enhance thermal retention without increasing material thickness. These designs help maintain beverage temperature longer and reduce hand discomfort. At Yongrui Packaging, we continuously refine our cup structure to achieve the perfect balance between comfort and heat resistance, ensuring consistent performance even during large-scale production runs.

Eco-Friendly Coatings and Barrier Materials

Traditional polyethylene (PE) coatings are gradually being replaced by water-based or bio-based coatings that allow easier recycling. These coatings offer excellent resistance to moisture and oil while maintaining cup rigidity. The transition to eco-friendly coatings requires precise process control and coating uniformity. Our production base is equipped with adaptable coating lines that enable quick switching between PE and biodegradable coating types, helping customers meet different environmental regulations efficiently.

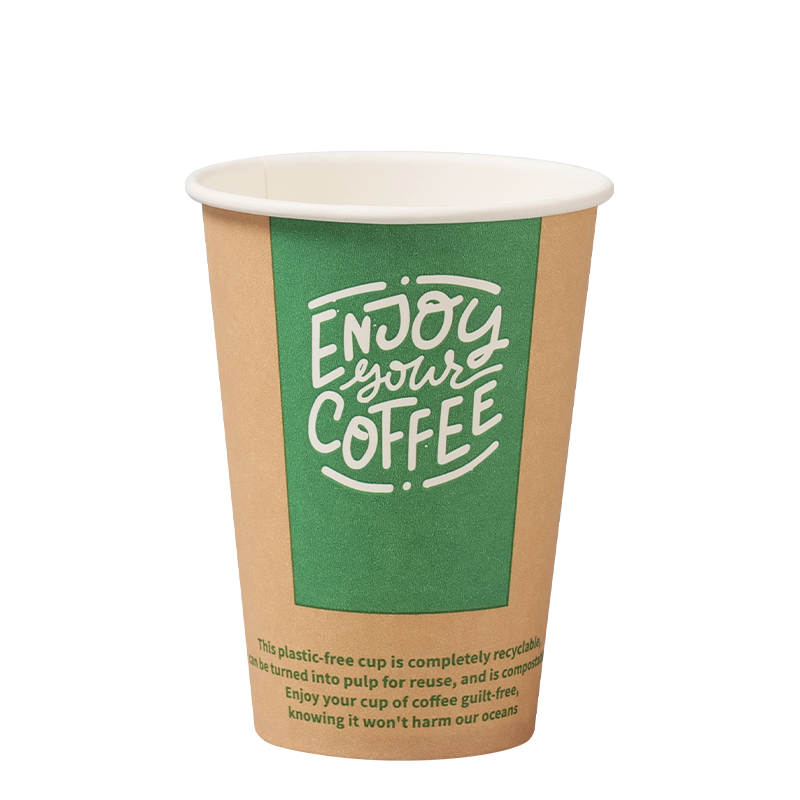

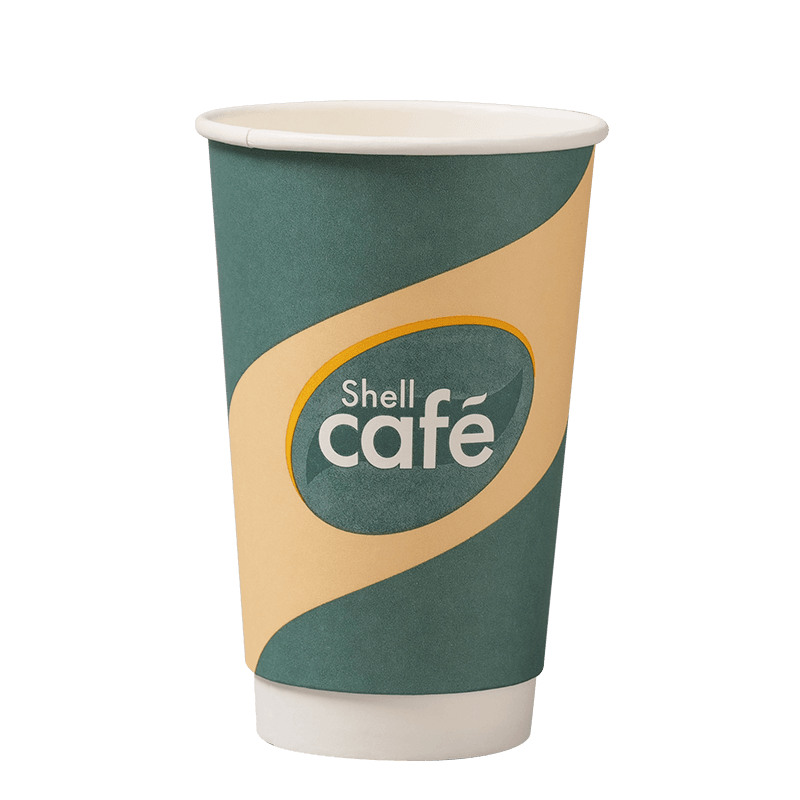

Print Quality and Brand Presentation in Paper Coffee Cups

High-quality printing on paper coffee cups plays a vital role in brand recognition. Modern flexographic and digital printing technologies allow for sharper images, better color consistency, and faster turnaround times. Factors such as ink absorption rate, drying temperature, and surface smoothness all affect the final print quality. Our in-house printing systems are calibrated to maintain vivid colors across large batches, ensuring every cup carries the same professional appearance that strengthens our partners’ branding efforts.

Comparative Durability of Single-Wall and Double-Wall Cups

| Feature |

Single-Wall Cup |

Double-Wall Cup |

| Heat Insulation |

Moderate |

Excellent |

| Material Usage |

Lower |

Higher |

| Typical Applications |

Cold or room-temperature drinks |

Hot beverages like coffee or tea |

Selecting between these two types often depends on beverage temperature and brand preference. Our flexible production setup allows us to shift between single-wall and double-wall configurations effortlessly, offering customers reliable delivery even for mixed product portfolios.

Quality Control Methods for Large-Volume Orders

Maintaining uniform quality in high-volume runs requires strict monitoring at every production stage. Typical control points include paper weight measurement, coating integrity inspection, and leak testing. Automation in visual inspection and sample testing reduces human error while maintaining output speed. We take pride in our rigorous in-line testing systems, ensuring that every batch of disposable paper cups meets consistent standards before shipment.

Storage and Handling Recommendations for Paper Cups

- Keep cups in a dry, well-ventilated environment to prevent moisture absorption and deformation.

- Avoid stacking beyond manufacturer’s recommendations to maintain structural integrity.

- Rotate stock periodically to ensure older batches are used first, preserving optimal performance.

Even the most durable paper coffee cups can lose shape if stored improperly. That’s why we provide customers with detailed handling guides along with every shipment, part of our commitment to stable, long-term supply support.

+86-18863350588

+86-18863350588

English

English Français

Français Deutsch

Deutsch Español

Español