Industry Knowledge

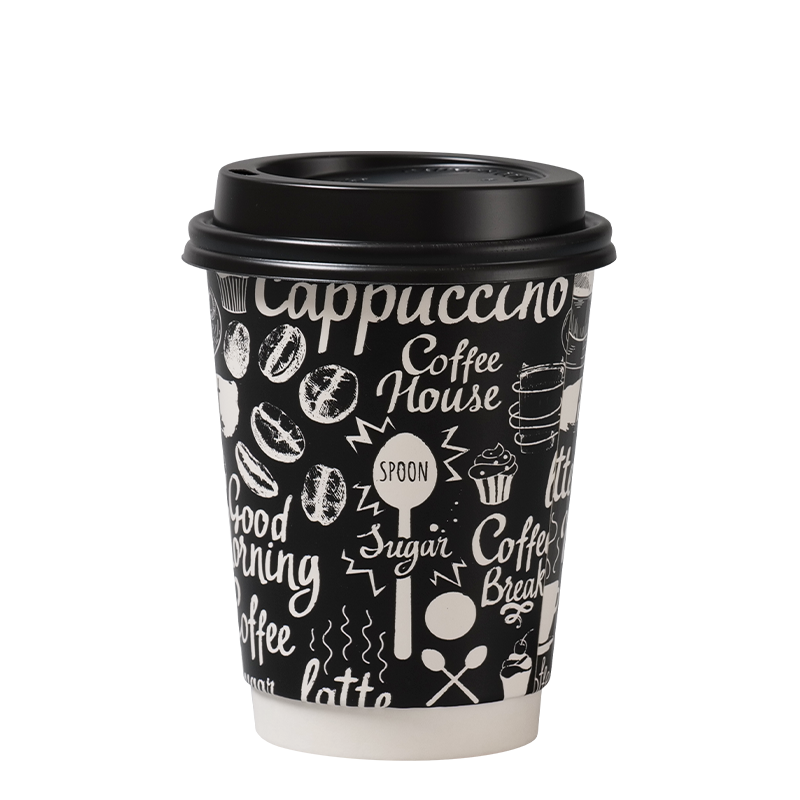

Thermal Performance and Grip Comfort of Double-Walled Paper Cups

In professional beverage service, one of the most overlooked yet crucial aspects is thermal comfort. When a hot drink reaches around 92°C, the ability of the cup to maintain structural integrity and prevent heat transfer directly affects user experience. Our field data indicates that double-walled cups reduce outer wall temperature by about 40% compared to standard single-walled cups. This difference is enough to let consumers comfortably hold a steaming beverage without a sleeve—something we take pride in achieving through precise wall spacing and controlled air-gap design.

Comparative Structure of Different Double-Wall Types

Double-walled paper cups come in various forms—each with distinct benefits suited to specific operational environments. While we offer three categories, the principles behind their design can help professionals choose the right option for their business or product line.

| Cup Type |

Structural Feature |

Best Use Scenario |

| Double-Walled Hollow Cup |

Air gap between two smooth layers |

Premium beverages and branding-focused cafes |

| Corrugated Paper Cup |

Outer corrugated layer for heat insulation and grip |

Takeaway and high-traffic environments |

| Embossed Paper Cup |

Textured embossing creates micro air pockets |

Stylish service and brand differentiation |

Mechanical Testing Beyond Industry Standards

Quality assurance for paper cups often stops at single liquid retention tests. However, when managing large-scale catering or international shipping, mechanical resistance becomes equally important. Our own process includes what we call a “double destructive test”—pressure and tear testing performed on cup bases, sidewalls, and seams. This dual testing simulates extreme use conditions, from vending machines to prolonged storage under weight. Personally, we find this step invaluable in ensuring zero leakage even when cups are filled and stacked under pressure.

Environmental and Operational Considerations

Beyond function, operators often need to balance comfort, durability, and sustainability. Choosing the right double-wall configuration can minimize material use without sacrificing insulation. For instance, embossed cups use less paper than corrugated ones while offering comparable heat resistance. By understanding this balance, businesses can optimize both performance and eco-impact—something we continuously refine through our manufacturing trials.

Practical Selection Tips

- Match the wall structure to beverage temperature and holding duration.

- For takeaway chains, corrugated walls offer maximum hand comfort and durability.

- Embossed walls serve best for branded events or stylish presentation.

- Hollow double-walls excel when insulation and premium appearance are priorities.

Consistency Through Controlled Manufacturing

In high-volume production, maintaining precise bonding between inner and outer layers is critical. Minor inconsistencies can lead to weak points or uneven insulation. Our production line employs continuous temperature calibration and optical seam inspection, ensuring that every cup meets consistent thermal and mechanical standards. In our experience, these technical refinements translate directly to better end-user satisfaction—and fewer customer complaints for our partners.

+86-18863350588

+86-18863350588

English

English Français

Français Deutsch

Deutsch Español

Español