Industry Knowledge

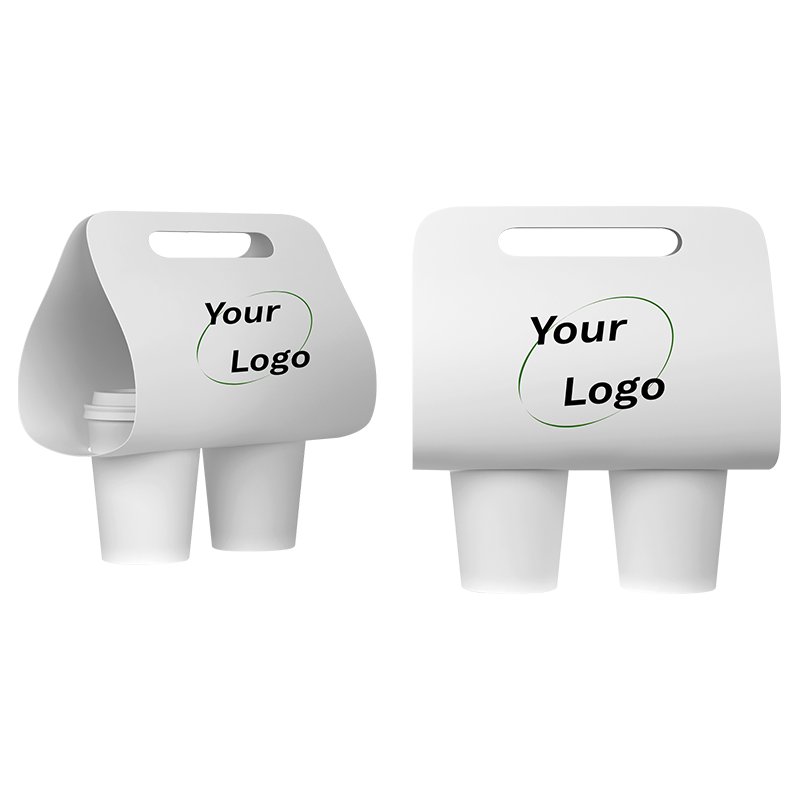

Structural features that combine stability with portability

The key to a one-piece takeaway paper handle holder is turning a flat sheet into an internal load-bearing frame through precision creasing and folding. Pre-creased lines define hinge points that, when pressed, form ribs and interlocking panels. These ribs transfer vertical loads into distributed compression across the paperboard web, so a single-handed grip supports multiple cups without localised failure. Critical dimensions—slot width, fold radius, and the depth of the cup well—are engineered to match the common 10oz/12oz/16oz cup geometries so that the holder both stabilises the cup laterally and preserves thermal insulation during transit.

Engineering the internal load-bearing frame

The internal frame relies on two design principles: geometric stiffness and controlled creasing. Geometric stiffness comes from converting flat panels into boxed sections—tabs lock into slots creating triangles and rectangular tubes that resist bending. Controlled creasing is implemented with specific scoring depths and spacing; too shallow and the fold won’t form a reliable rib, too deep and the fiber breaks, reducing strength. Optimising these parameters yields a handle holder that assembles tool-free in seconds yet can withstand dynamic loads equivalent to about 1kg—approximately three full cups under real delivery motion.

Assembly and performance in store operations

On the frontline, the holder’s design reduces handling time by removing separate steps for bagging and stabilising cups. Staff press along pre-creased lines to activate the load-bearing geometry; no adhesive or fixtures are required. This quick activation saves labor during busy periods and reduces the likelihood of improper assembly that can compromise safety. The compact flat storage form reduces inventory footprint by roughly 40% compared with paired carriers and bags, allowing outlets to hold more units in the same shelf area while simplifying reorder logic.

Material choices and food-contact safety considerations

Selecting food-grade virgin paper and kraft boards ensures structural consistency and avoids contaminants. Virgin fibre preserves tensile strength needed for engineered ribs; kraft board offers natural moisture resistance without chemical coatings. For printing, water-based inks provide vibrant full-surface graphics while remaining free from volatile organic compounds, preserving both food safety and compostability. Avoiding fluorescent whiteners or non-food-safe additives prevents off-odors and migration risks when holding hot beverages.

Durability vs biodegradability trade-offs

Designers must balance short-term mechanical durability with end-of-life decomposition timelines. Increasing fiber density and adding internal ribs improves load capacity but can slow biodegradation. A practical solution is to limit reinforcement to geometric forms rather than chemical treatments, achieving the required 1kg dynamic load performance while keeping decomposition within a natural 3–6 month window under typical soil conditions.

Operational metrics and testing protocols

Quantifiable testing ensures designs meet both stability and portability claims. Dynamic-load testing simulates real delivery movements—vertical shakes, lateral jolts, and continuous sway—to validate that the assembled holder retains grip and shape. A standard protocol might include cyclic loading at 1kg for 1,000 cycles, drop tests from common delivery heights, and humidity exposure to check pre-use storage robustness. Recordable pass/fail metrics help foodservice operators predict replacement rates and plan inventory.

| Specification |

Typical value |

Operational impact |

| Compatible cup sizes |

10oz / 12oz / 16oz |

Reduces SKU complexity; fits mainstream beverage cups |

| Dynamic load capacity |

~1 kg |

Supports up to 3 cups during delivery motion |

| Storage form |

Flat, pre-creased sheet |

40% reduction in storage volume vs separate carriers+bags |

| Material |

Food-grade virgin paper / kraft |

Biodegradable; safe for hot beverages |

| Printing |

Full-surface, water-based inks |

Branding without VOC emissions |

Design guidelines for adoption and quality control

When integrating handle holders into a takeaway workflow, prioritize measurable tolerances and clear assembly cues. Specify scoring depths, fold radii, and slot tolerances in supplier drawings; require factory gauging with go/no-go fixtures to prevent variance. Insist on batch testing that replicates store environmental conditions—temperature swings, humidity, and stacked storage—to ensure holders arrive in consistent condition and perform reliably during peak service.

- Provide staff with simple visual guides showing where to press and how to lock tabs to reduce assembly errors.

- Require suppliers to submit dynamic load and drop-test reports as part of acceptance criteria.

- Plan SKU consolidation: use one holder design across multiple cup sizes when possible to simplify ordering and training.

User experience and branding opportunities

Beyond function, the takeaway paper handle holder becomes a customer touchpoint. Full-surface printability allows for instructional icons, safety messaging, and promotional art that reinforce proper handling and disposal. Clear disposal icons and short composting guidance help close the loop on sustainability while branded graphics increase perceived value during last-mile delivery.

Final considerations

Integrating cup stability and portability in a single-sheet handle holder is an exercise in precision engineering, practical materials selection, and operational alignment. When the creasing geometry, material grade, and testing protocols are correctly specified and enforced, the result is a compact, efficient, and safe solution that enhances delivery reliability while supporting sustainable end-of-life outcomes.

+86-18863350588

+86-18863350588

English

English Français

Français Deutsch

Deutsch Español

Español