Industry Knowledge

Transforming natural fiber into structural strength

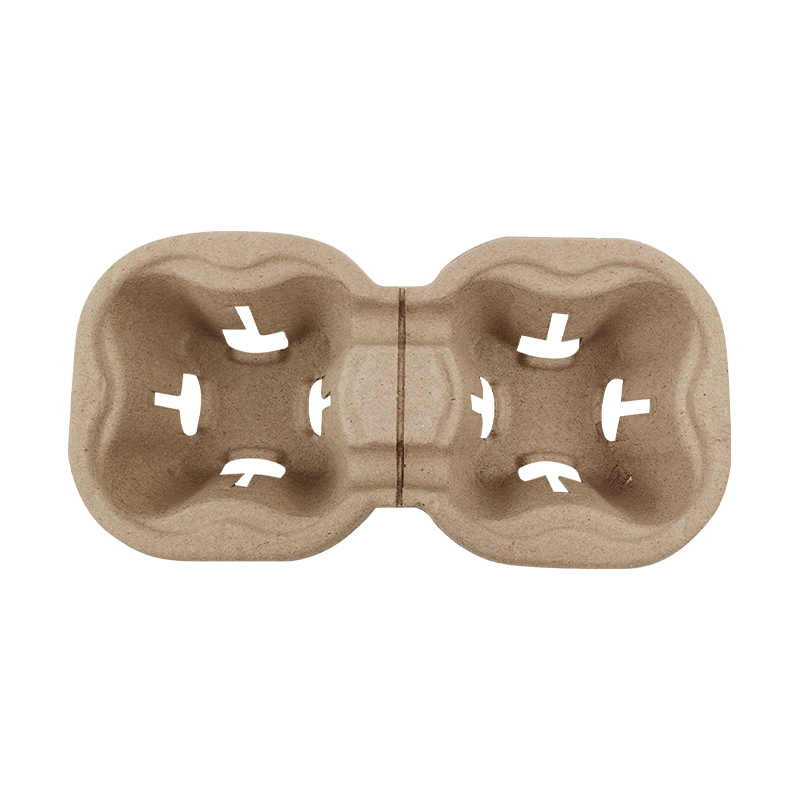

The journey from fiber to form begins with the selection of high-purity wood pulp. To create drink carrier trays that are both durable and fully degradable, manufacturers rely on mechanical refining rather than chemical bleaching, preserving the cellulose’s natural binding properties. When pulp is pressed under high temperature and pressure, the fibers interlock densely, producing a rigid yet lightweight matrix. This physical bonding eliminates the need for synthetic binders, resulting in packaging that is safe for direct food contact and free from fluorescent agents or ink residue.

At Yongrui Packaging, molding precision plays a decisive role. The fiber slurry is carefully metered into automated molds that define the depth and elasticity of each cup slot. Controlling moisture during compression determines the final strength-to-weight ratio—a key factor for both performance and compostability. The result is a drink carrier tray capable of withstanding transport shocks while remaining fully biodegradable after disposal.

Biodegradation: the science behind soil return

Unlike synthetic materials that fragment into microplastics, molded pulp disintegrates through microbial activity once exposed to natural soil conditions. Moisture, oxygen, and microorganisms gradually break down cellulose chains, converting them into carbon dioxide, water, and biomass. This decomposition process varies depending on humidity, soil pH, and fiber density, but in managed composting environments, full degradation typically occurs within 60–90 days.

| Environmental condition |

Approximate degradation time |

Resulting output |

| Industrial composting (55–60°C) |

45–60 days |

CO₂, H₂O, organic compost |

| Moist garden soil |

90–120 days |

Nutrient-rich humus |

| Dry landfill condition |

Over 200 days |

Slow fiber decomposition |

Optimizing molding for circular sustainability

To close the material loop, it is not enough that drink carrier trays are biodegradable—the production must also minimize energy use and waste generation. At Yongrui Packaging, automated pulp molding lines recycle process water multiple times, capturing fiber residues and reintegrating them into the slurry. Mold temperatures are precisely monitored to balance curing efficiency with energy savings, while exhaust air from the drying tunnel is filtered and reused in pre-heating zones. Such refinements significantly lower the carbon intensity of each tray produced.

This circular production model extends beyond the factory floor. Once discarded, used trays can be collected alongside paper waste or compostable materials, returning to the natural cycle as organic matter. Each step—from forming to decomposition—reflects a full-circle design philosophy rooted in practical sustainability rather than symbolic recycling.

Practical considerations for end users

Operators in the beverage and delivery sectors can enhance the eco-performance of soil-degradable trays by matching usage patterns with disposal infrastructure. Trays made from 100% wood pulp perform best when composted rather than landfilled. Encouraging collection through dedicated bins or partnerships with local compost facilities maximizes environmental benefit. In markets where composting access is limited, promoting reuse for short-term internal transport can extend their functional life before disposal.

- Store trays in dry environments to prevent premature softening before use.

- Educate delivery partners on tray compostability to ensure correct waste sorting.

- Avoid overloading carriers beyond their designed cup diameter to maintain structural integrity.

A fiber-to-soil model shaping packaging’s future

The “from fiber to form” cycle exemplifies how innovation in molded pulp packaging transforms renewable raw materials into functional, safe, and naturally degradable products. By aligning design precision, controlled production, and verified end-of-life performance, companies like Yongrui Packaging demonstrate how industrial-scale manufacturing can harmonize with ecological cycles. Each tray produced represents a tangible step toward waste-free food delivery—proof that effective design and environmental integrity can coexist within the same product lifecycle.

+86-18863350588

+86-18863350588

English

English Français

Français Deutsch

Deutsch Español

Español