Industry Knowledge

Balancing Transparency and Strength in PS Cup Lid Design

High-transparency PS cup lids provide exceptional clarity that enhances product visibility in cold beverage packaging. However, achieving both transparency and sufficient structural strength requires a precise balance in raw material formulation and injection molding parameters. Adjusting molecular weight distribution and cooling rates during molding can prevent brittleness while maintaining optical clarity. Manufacturers often modify wall thickness and edge curvature to enhance impact resistance without compromising the visual presentation of the drink.

Injection Molding Techniques for High-Gloss Finishes

The glossy finish of PS cup lids is not only aesthetic but also functional, reducing water spot visibility and improving consumer perception of cleanliness. To achieve this, injection molding temperature control and mold surface precision are critical. Highly polished steel molds and controlled cooling cycles prevent haze formation, while advanced mold venting systems help eliminate gas marks. Process optimization enables consistent production of lids with uniform gloss and dimensional accuracy, key factors in large-scale beverage packaging.

How Lid Geometry Affects Drink Experience

The design geometry of PS cup lids influences both consumer convenience and sealing performance. Dome-style lids are suitable for beverages with toppings such as whipped cream or ice, while flat lids are more effective for straw insertion and stacking. Rim curvature and snap-fit groove depth determine the sealing tightness, directly impacting leak prevention during transportation. A well-engineered lid design not only protects the beverage but also enhances brand image through ergonomic and aesthetic appeal.

Environmental Adaptability of PS Cup Lids in Cold Chain Logistics

In cold beverage distribution, temperature fluctuations during storage and transport can affect material stability. High-quality PS cup lids are engineered to maintain rigidity and prevent deformation under low temperatures commonly found in refrigerated conditions. Anti-cracking additives and precise polymer chain control help maintain structural integrity, ensuring that the lids retain their form even after repeated exposure to condensation or brief temperature changes.

Comparative Overview of PS and PET Materials in Beverage Packaging

| Property |

PS Cup Lids |

PET Cup Lids |

| Transparency |

Excellent, crystal-clear |

High, slightly bluish tone |

| Temperature Resistance |

Best for cold beverages |

Tolerates mild heat |

| Impact Strength |

Moderate, can crack under stress |

High, resists impact well |

| Cost Efficiency |

Lower production cost |

Higher material cost |

Customization Options Enhancing Brand Identity

High-transparency PS cup lids can be customized through mold engraving, surface printing, or color blending to reinforce brand visibility. Embossed logos create tactile branding, while UV-resistant color additives maintain visual appeal under store lighting. Manufacturers serving international beverage chains often provide lid variations compatible with multiple cup diameters, improving logistics efficiency and maintaining brand uniformity across markets.

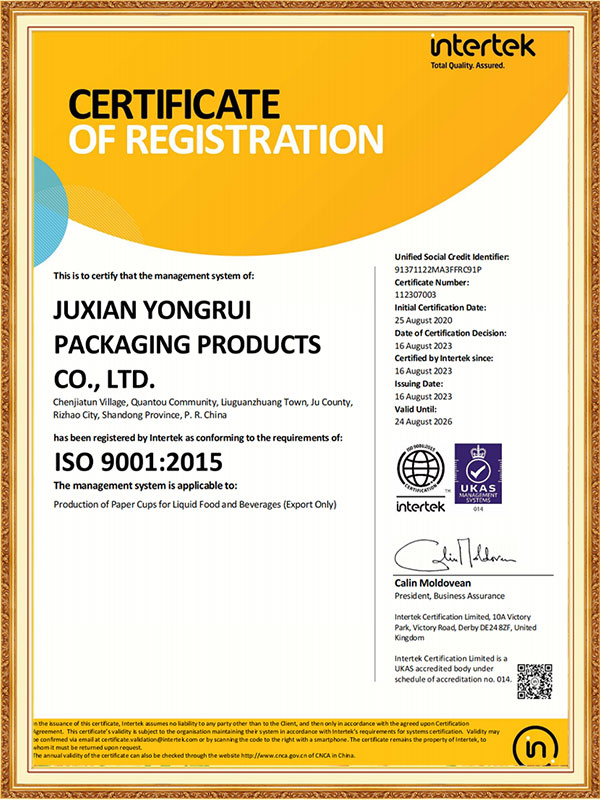

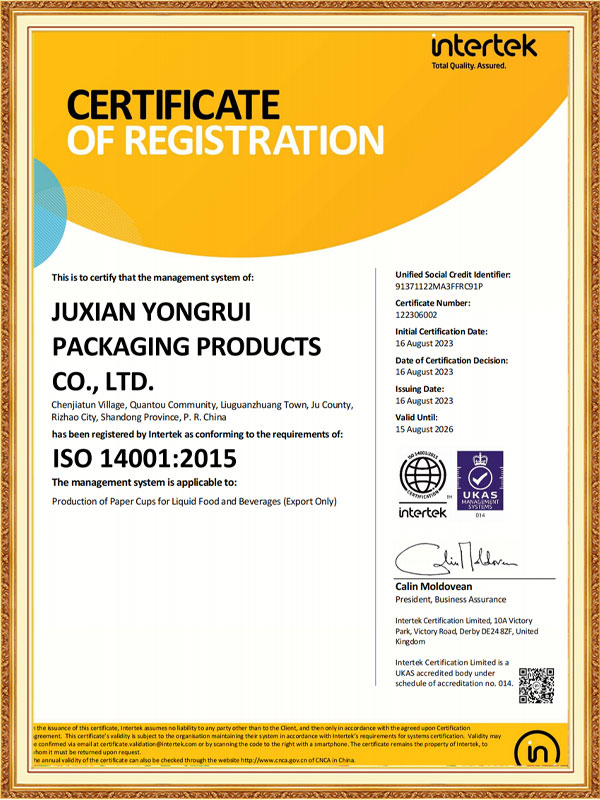

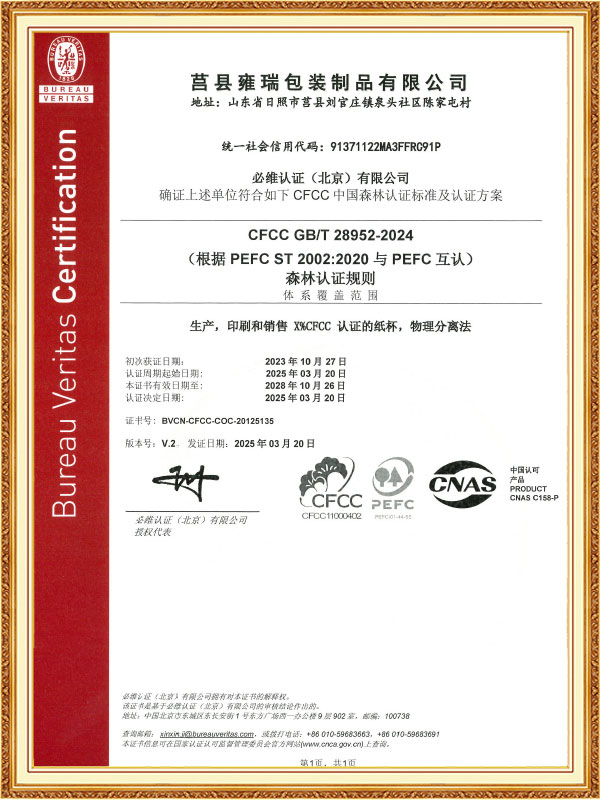

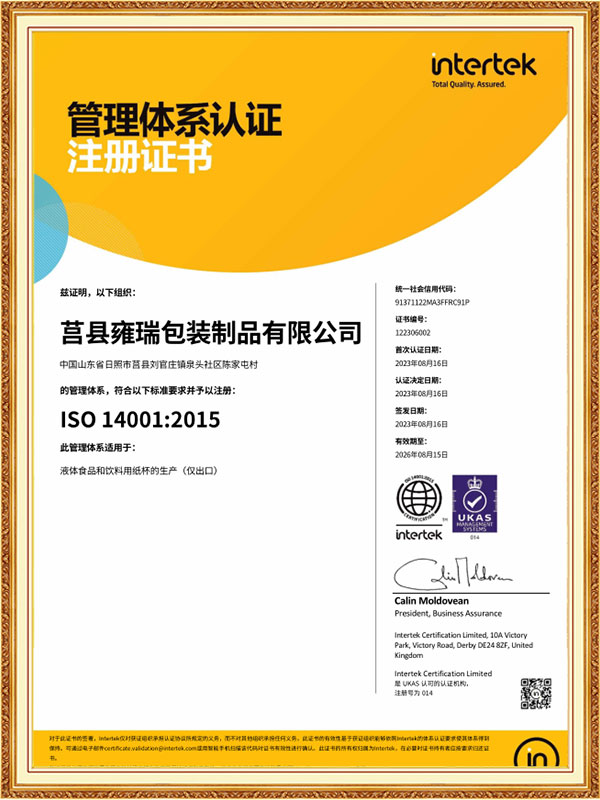

Quality Control Standards for Food-Grade PS Cup Lids

Strict quality control ensures that PS cup lids meet hygiene and performance requirements for food packaging. Testing includes migration analysis, sealing performance, transparency measurement, and stress crack evaluation. Production facilities certified with ISO 9001 and BRC standards employ inline inspection systems that monitor lid dimensions and detect defects in real-time. This approach guarantees that every lid meets international safety and consistency standards.

Recycling Challenges and Innovation in PS Material Recovery

Although PS has recycling challenges due to density and sorting limitations, innovative mechanical and chemical recycling methods are improving its sustainability potential. Advanced depolymerization techniques can convert used PS into monomers for reuse, significantly reducing waste. Additionally, blending recycled PS with virgin materials under controlled conditions can maintain clarity and strength, aligning with the packaging industry's shift toward circular economy models.

Emerging Trends in Cold Beverage Packaging

As consumers demand more eco-conscious yet visually appealing packaging, the trend toward hybrid materials and minimalist design continues to rise. Some beverage brands are integrating biodegradable coatings or exploring multi-layer PS composites to improve recyclability while retaining transparency. Smart lid features such as temperature-indicating color shifts or spill-control valves are also under development, demonstrating how PS packaging continues to evolve beyond traditional designs.

+86-18863350588

+86-18863350588

English

English Français

Français Deutsch

Deutsch Español

Español