Industry Knowledge

Thermal behavior of PP in hot beverage applications

Polypropylene (PP) is valued for its stable performance at elevated temperatures, making it suitable for lids used with beverages up to 120°C. When heated, PP transitions through a crystalline phase that provides dimensional stability without softening or releasing odor. However, production must carefully control melt-flow index and isotactic content to prevent warping under sustained heat. Manufacturers often run simulation tests that cycle lids through heating and cooling to confirm sealing integrity and deformation limits before mass production.

Optimizing lid fit for various cup materials

PP cup lids are used across paper, PET, and PLA cup types, but the different rim hardness and tolerance levels require tuning lid dimensions. Precision thermoforming tools maintain ±0.1 mm tolerances at the rim groove to ensure leak-free sealing. Engineers commonly use pressure-fit or snap-on interface tests at multiple temperatures to evaluate fit retention and avoid lid loosening when hot steam softens cup edges.

- Paper cups expand slightly under steam; lid grooves must compensate with added elasticity.

- PET cups retain shape under heat but require slightly tighter sealing lips for secure closure.

- For PLA cups, lower thermal limits require testing to prevent cracking during lid application.

Evaluating flexibility and impact resistance

PP lids undergo repeated flexing and mechanical stress during packaging, transportation, and customer use. Impact resistance is measured through drop testing, often from 1.2 meters, simulating stacking and cup handling. The lid’s polymer chain length and orientation after thermoforming influence its toughness. To improve resilience, manufacturers may modify mold cooling rates, which increases molecular orientation and boosts elastic recovery without making the material brittle.

Key performance benchmarks

| Test Item |

Target Value |

Evaluation Method |

| Flexural Strength |

≥ 90 MPa |

Three-point bending test at 23°C |

| Drop Impact Resistance |

No cracks or deformation after 5 drops |

Free-fall test from 1.2 m height |

| Elastic Recovery |

≥ 95% |

Rebound rate after compression |

Food-contact compliance and migration testing

Food-grade PP must meet migration limits set by FDA and EU regulations. These tests simulate prolonged exposure to hot liquids and fatty substances to confirm that the lid does not release harmful compounds. Migration testing typically uses simulants such as 3% acetic acid, 10% ethanol, and isooctane at 100°C for up to two hours. Only after migration levels remain below 10 mg/dm² can materials be certified as food-safe. Documentation of each raw-material batch ensures consistent traceability.

Maintaining lid clarity and surface finish during production

Though PP is slightly hazier than PET, precise molding parameters can enhance clarity and surface gloss. Mold temperature control between 15°C and 25°C prevents surface whitening caused by uneven crystallization. Additionally, anti-fog and scratch-resistant coatings can be applied for beverage lids requiring transparency, such as for cold or mixed-temperature drinks. Balancing clarity and rigidity is a key production challenge that influences customer satisfaction and brand perception.

Heat-sealing and leak-prevention improvements

For takeaway beverages, sealing performance is critical. PP cup lids can be optimized with micro-seal ridges or vent channels to release steam pressure without leakage. Some advanced lid designs use multi-point vent holes that maintain internal pressure balance, avoiding splash when the cup is shaken or the lid is pressed. Manufacturers often perform pressure-retention and leak tests under different liquid temperatures to refine sealing geometry.

- Steam vents reduce lid lift-off risk during pouring.

- Double-seal structures create stronger locking friction between cup rim and lid groove.

- Tapered edges improve ergonomic grip and minimize hand slip when closing the lid.

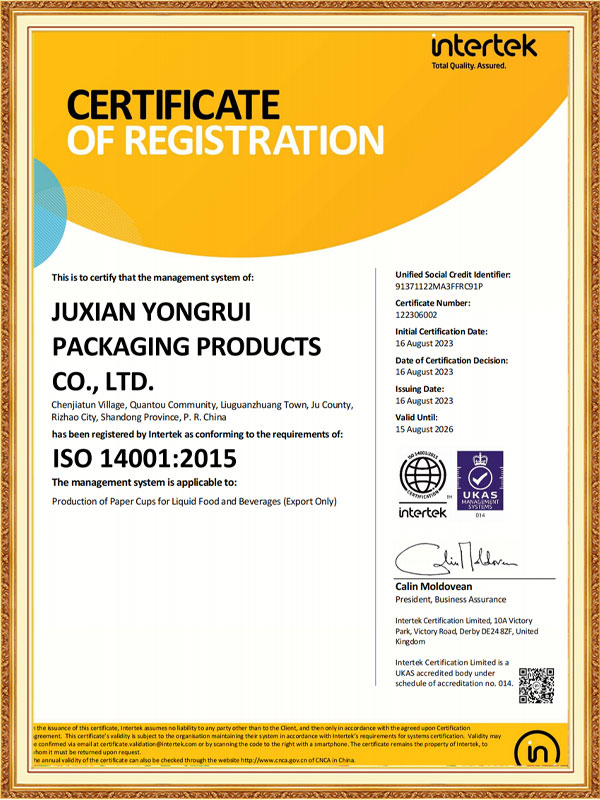

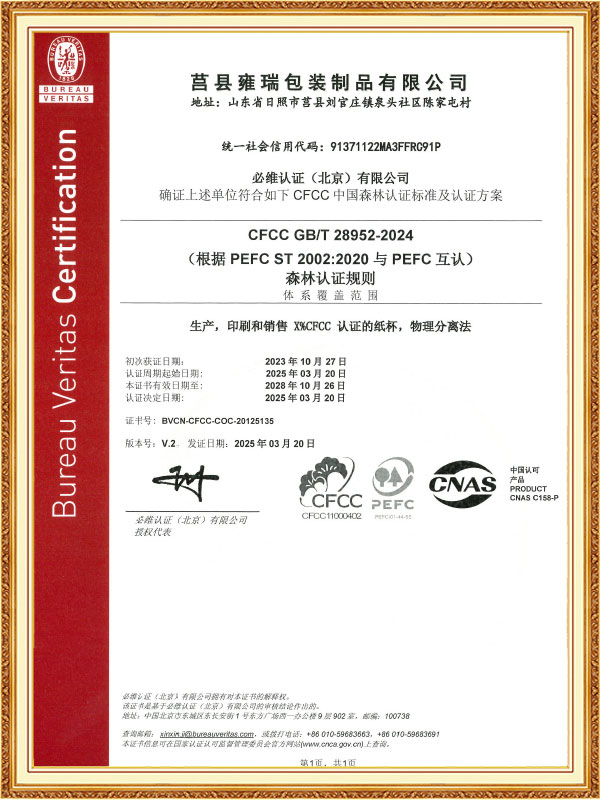

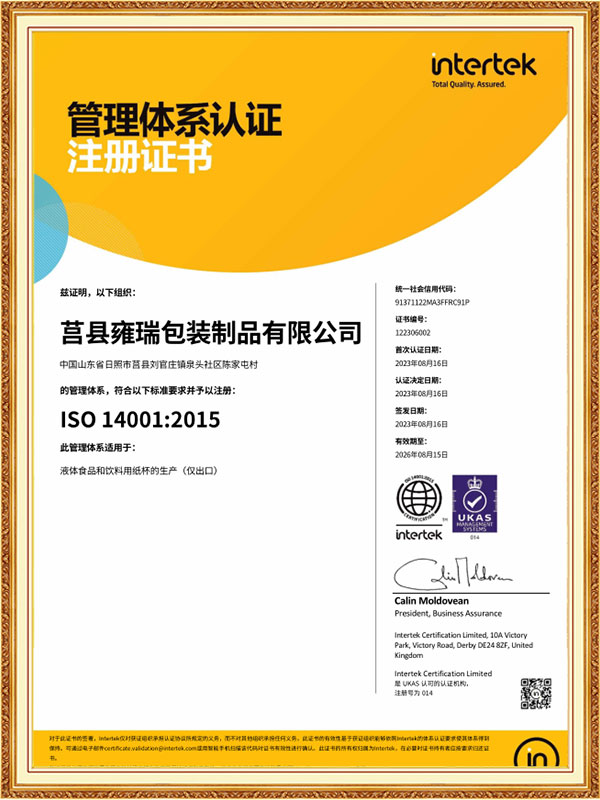

Sustainability aspects in PP lid production

Although PP is a thermoplastic derived from petroleum, it remains one of the most recyclable food-grade polymers due to its clean melting profile and low degradation rate. Closed-loop recycling programs can reprocess post-industrial waste into non-food applications. Incorporating bio-based PP resins, derived from renewable naphtha or plant oils, further reduces carbon footprint. Implementing these measures aligns with sustainability standards such as ISO 14001 and supports global environmental goals.

+86-18863350588

+86-18863350588

English

English Français

Français Deutsch

Deutsch Español

Español