Industry Knowledge

Material Selection: increasing PCR content and choosing recyclable PET

Selecting the right resin and increasing post-consumer recycled (PCR) content are two practical levers to reduce lifecycle impact for PET cup lids. Increasing PCR content requires close raw-material testing to avoid color, odor, and mechanical-performance variability. In practice this means establishing tight incoming-quality specifications for PCR batches (IV range, contaminant limit, color tolerance) and blending strategies that mix virgin and PCR PET to achieve consistent melt flow and clarity while meeting food-contact migration limits.

Practical steps for PCR integration

- Qualify multiple PCR suppliers and insist on traceable PCR certificates that document source streams and contamination controls.

- Use small pilot runs to dial in extrusion and thermoforming parameters for each PCR blend before scale-up.

- Maintain clear product SKUs for different PCR percentages so downstream recyclers can separate feedstock streams if needed.

Design for recyclability: mono-material and lightweighting strategies

Design choices strongly influence whether a PET lid is actually recycled at end-of-life. Two high-impact design rules are using mono-material constructions (avoid mixing PET with incompatible plastics or complex multi-layer coatings) and reducing material use through thickness optimization and geometry changes that preserve function.

Concrete design actions

- Prefer clear or light-tinted PET over dark pigments; dark colors often fail optical sorting and reduce recycling yield.

- Eliminate non-PET inserts, adhesives, or inks that interfere with melt filtration and remelting.

- Use ribbed or structural geometry to maintain rigidity while thinning wall sections for lightweighting.

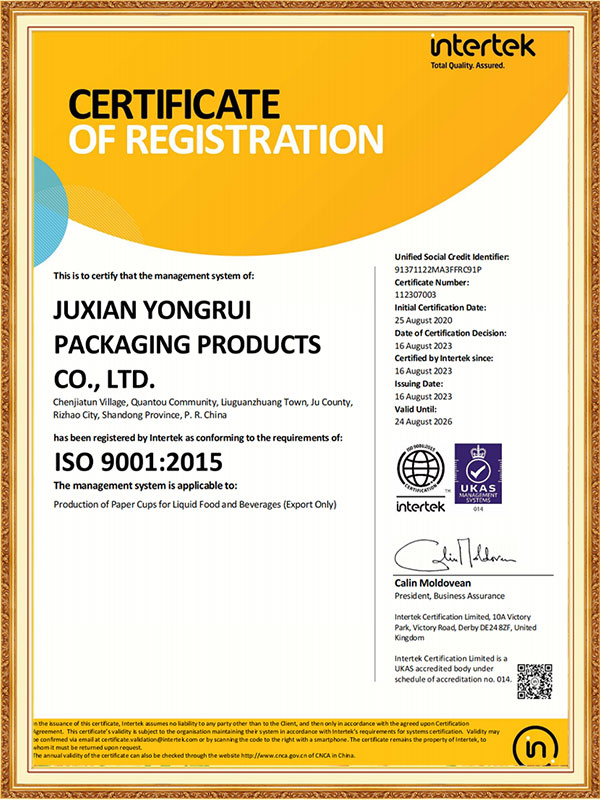

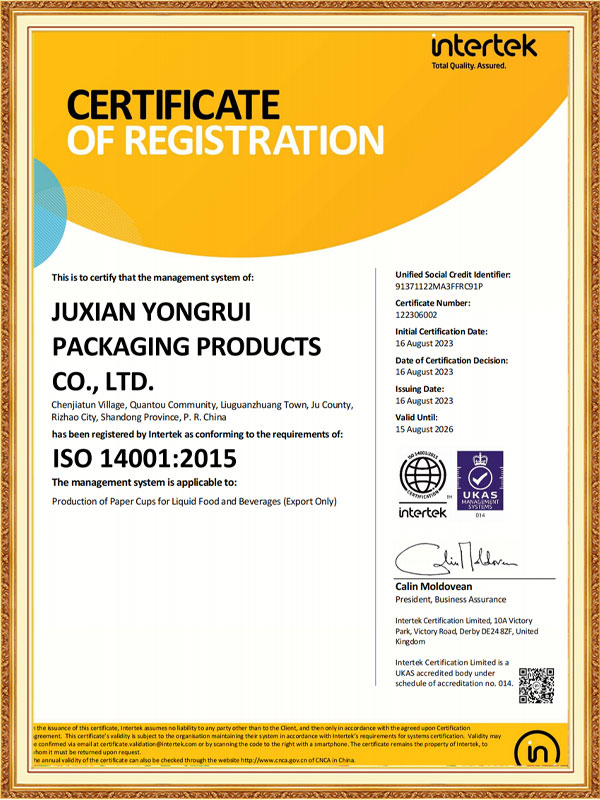

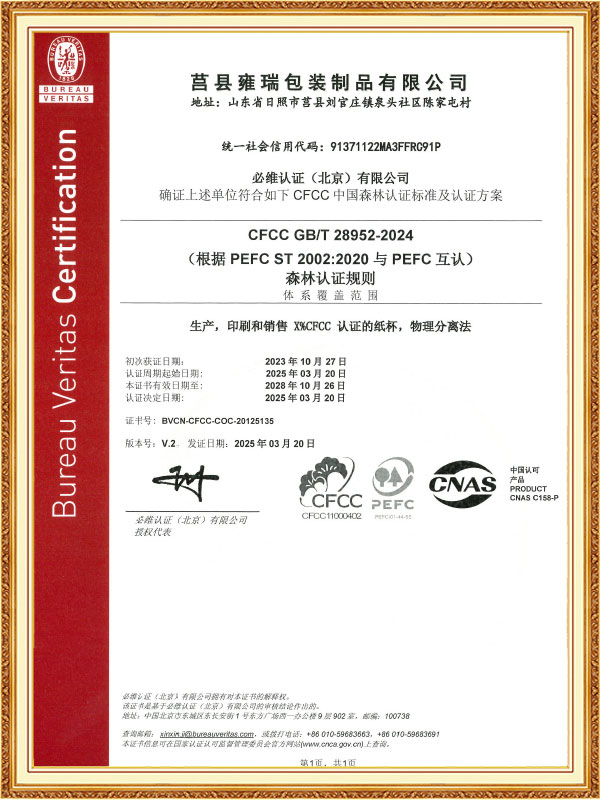

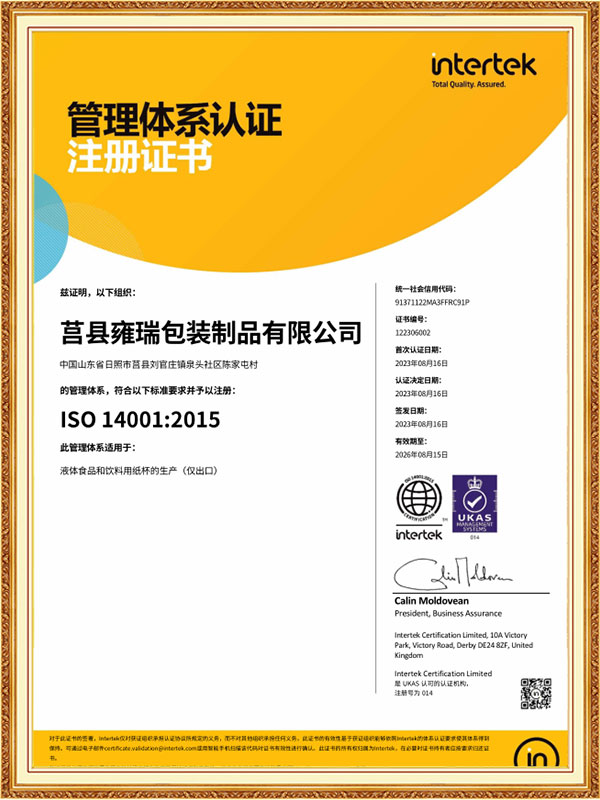

Manufacturing controls and certifications that support green claims

Robust management systems and third-party certifications translate internal practices into verifiable claims. Certifications such as ISO 9001 and ISO 14001 require documented procedures for quality and environmental management. BRC and relevant food-safety standards ensure processes limit contamination risks when using recycled content in food-contact applications. Implementing these systems means regular internal audits, supplier audits, and traceable batch records from raw material receipt to finished-lid shipment.

How to operationalize certification benefits

- Use ERP-driven traceability so each production run links to specific raw-material lots, PCR certificates, and QA test results.

- Schedule periodic supplier verification for PCR feedstock and request contamination test reports (metal, PVC, moisture).

- Document energy and waste metrics to feed ISO 14001 continuous-improvement plans and show progress on footprint reduction.

Testing and quality assurance specific to PET lids with recycled content

When incorporating recycled material, testing expands beyond dimensional tolerances. Key tests include melt-flow index (MFI) or intrinsic viscosity (IV) checks, color and odor panels, extractables/migration tests for food safety, oxygen and moisture barrier performance where applicable, and mechanical testing for lid fit and sealing force. Establishing acceptance criteria and rollback procedures protects customers and the brand.

| Test |

Purpose |

Action if out of spec |

| IV / MFI |

Ensure consistent melt behavior |

Adjust blend ratio or quarantine batch |

| Migration / Extractables |

Verify food safety with recycled content |

Reject material; investigate contamination source |

| Color & Odor |

Maintain brand appearance and user acceptance |

Refine PCR sorting or increase virgin ratio |

Logistics, ERP, and circular-economy partnerships

A circular approach extends beyond product design into logistics and partnerships. Practical measures include using ERP data to minimize transport miles through regional warehousing, partnering with local collection and MRF operators to increase PET yield, and offering take-back or closed-loop programs with large customers to secure clean material streams for higher-quality PCR.

Tactical logistics and partnership actions

- Segment customers by geography in the ERP to optimize container consolidation and reduce per-unit transport emissions.

- Negotiate co-processing agreements with recyclers to accept off-spec PET cup lids for mechanical recycling rather than landfilling.

- Provide customers with clear end-of-life sorting instructions (e.g., rinse, keep lid attached/separate depending on local recycling rules) to improve collection quality.

Continuous improvement: metrics to track and report

To demonstrate genuine commitment, track specific KPIs: percentage PCR used by weight, per-unit material weight reduction (g/lid), energy use per tonne produced, yield of first-pass quality, and rate of product-to-recycle diversion. Reporting these metrics regularly—with third-party verification where possible—turns sustainability statements into actionable progress that customers and regulators can evaluate.

+86-18863350588

+86-18863350588

English

English Français

Français Deutsch

Deutsch Español

Español