Industry Knowledge

Material choices and carbon footprint: what to measure

When evaluating paper cup lids within a low-carbon coffee strategy, measure more than raw material origin. Track the full life-cycle: raw-material sourcing (FSC, EUDR-compliant pulp), water-based coating production, energy used during converting, transport distances, and end-of-life scenarios. A lid made from responsibly sourced fiber but shipped long distances and incinerated at end-of-life can carry a higher net carbon burden than a locally produced alternative.

Use a simple LCA checklist at the procurement stage: fiber certification, coating chemistry (water-based vs solvent-based), manufacturing energy source (grid mix vs renewables), packaging density (how many lids per pallet), and typical disposal route in target markets (municipal composting, industrial composting, landfill, or recycling stream). This checklist yields actionable procurement criteria rather than vague sustainability claims.

Design details that cut emissions in practice

Small design choices have outsized effects on supply-chain emissions and customer experience. A precision snap-on mechanism that fits multiple standard cup diameters (8oz–24oz) reduces SKU proliferation and production runs, cutting tooling and setup emissions. Similarly, an optimised spout size that allows spill-free drinking without extra plastic inserts reduces material use while maintaining user satisfaction.

Consider wall thickness and coating strategy together. A slightly increased paperboard grammage paired with an efficient water-based coating can outperform ultra-thin paper with multiple laminated layers when evaluated for durability, leakage resistance, and carbon intensity per functional use (i.e., per successful drink served without replacement).

Performance under real café conditions

Paper cup lids used in busy cafés face high-stress scenarios: hot pour-and-carry, condensation from iced beverages, and repeated staff handling. Choosing lids with validated temperature resistance (safe up to 100°C) and grease/moisture resistance through food-grade, water-based coatings prevents customer complaints and reduces waste from failed lids. A stable, well-fitting lid lowers the rate of single-use lid replacements during service peaks.

- Specify temperature tolerance in supplier contracts and request batch test reports showing non-warping performance at peak service temperatures.

- Require leak and fit tests on mixed cup/lid combinations typical to your operation, not just ideal lab pairings.

- Ask suppliers for real-world failure rate data (e.g., percentage of lids returned or replaced due to fit/warping) to estimate waste reduction potential.

End-of-life and collection: practical pathways

A low-carbon claim becomes credible only when supported by feasible end-of-life pathways. Paper lids with water-based coatings can be industrially compostable if certified; however, local infrastructure matters. If municipal composting is unavailable, focus on maximizing material recyclability or supply chain take-back programs.

Implement these operational steps in your outlets to improve outcomes:

- Clear staff training on separating lids from mixed waste streams and signage for customers about correct disposal options.

- Partner with local waste haulers to pilot compost collection for paper lids and measure contamination rates by volume weekly for the first 90 days.

- Run small-scale on-site collection trials to test whether customers will return lids to a dedicated bin for composting or recycling.

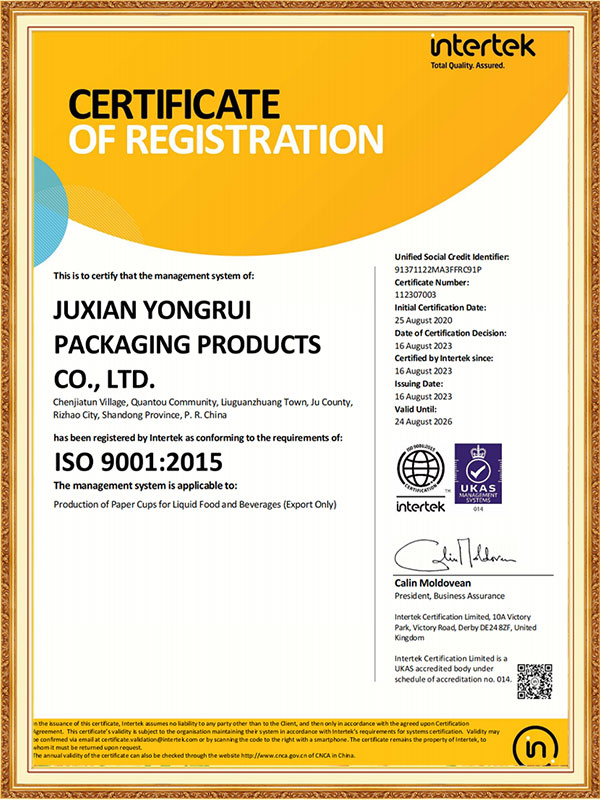

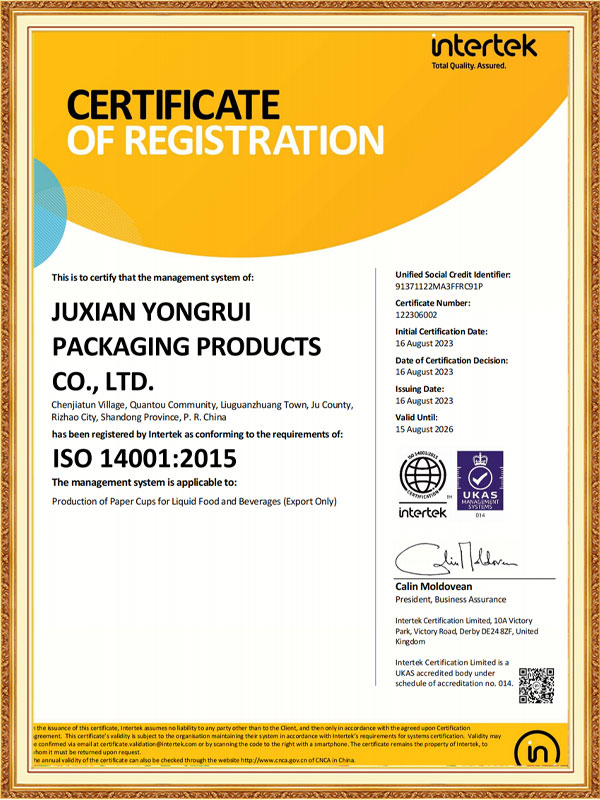

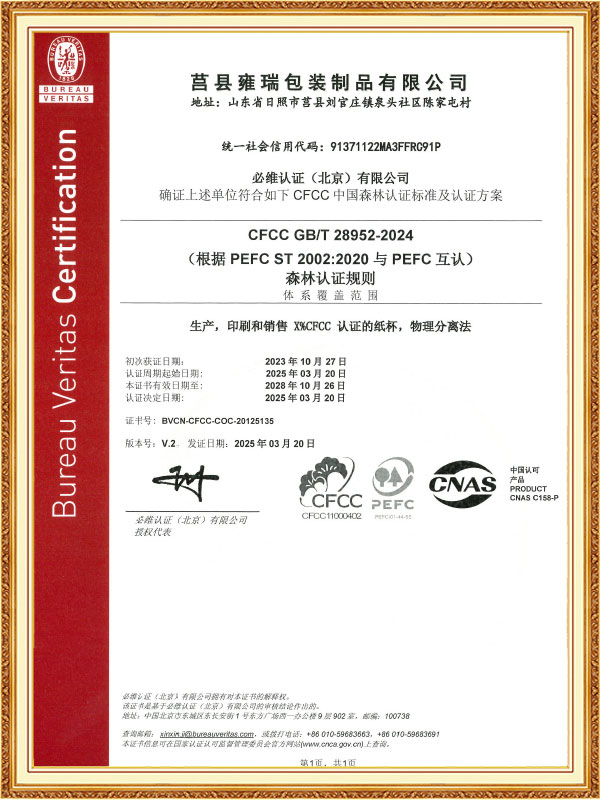

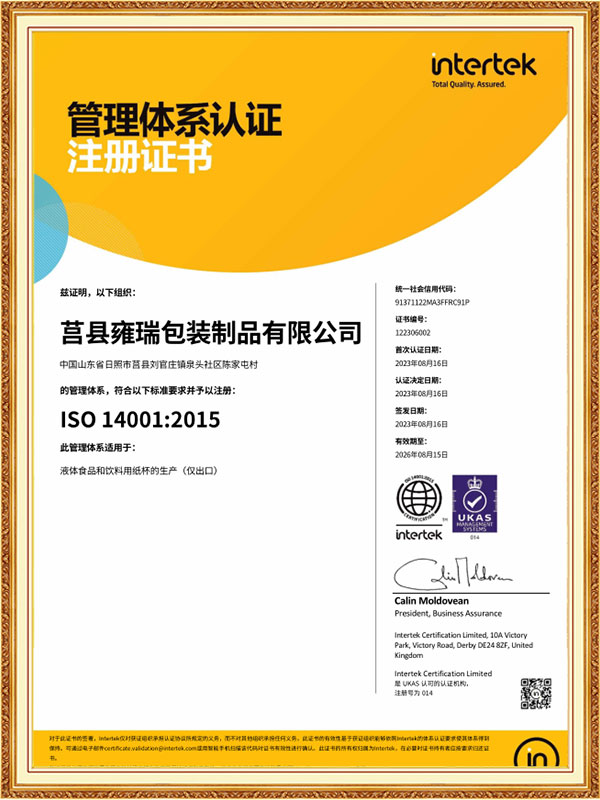

Certifications and supplier claims you can verify

Relevant third-party certifications improve transparency and provide audit points. Key items to require in supplier documentation include:

- FSC chain-of-custody for fiber sourcing to verify sustainable forestry practices.

- ISO 14001 for environmental management systems and ISO 9001 for quality control routines that reduce rework/waste.

- BRC or DIN certifications where relevant to food-contact safety and compostability standards.

How branding and customization support low-carbon goals

Custom printing on lids—logos, environmental messages, disposal instructions—adds marginal emissions for ink and print runs but delivers concrete returns: increased brand recognition and improved customer disposal behavior. Print variable messages that encourage correct disposal (e.g., 'Please compost here' with a clear icon) and track changes in contamination rates to quantify the benefit.

To minimize environmental impact from printing, use water-based inks, request minimal color separations, and consolidate printed SKUs to reduce make-ready waste at the converting stage.

Supply logistics that reduce the carbon footprint

Choose suppliers with high production capacity and efficient packing (e.g., Yongrui’s high-output automated lines) to lower per-unit transport emissions. Consolidated monthly shipments and full-container loads reduce per-lid transport footprint compared with frequent, smaller shipments.

| Lid type |

Temperature tolerance |

End-of-life |

Recommended use |

| Paper with water-based coating |

Up to 100°C |

Industrial composting / some municipal compost streams |

Cafés aiming for compostable serviceware |

| Paper with PLA lining |

Moderate (varies) |

Industrial composting only; not recyclable in paper stream |

Markets with industrial compost infrastructure |

| Rigid plastic lids |

High |

Recyclable where plastic stream collected |

Long-distance delivery or markets lacking composting |

Operational checklist for cafés

Adopt these steps to integrate paper cup lids into a low-carbon service model: contract suppliers with clear certification, run fit and temperature tests, harmonize cup and lid SKUs to reduce inventory complexity, trial local compost collection, and print simple disposal guidance on the lid. Track failure and contamination rates for three months to measure improvements and iterate.

Metrics to monitor

- Lid failure rate per 10,000 served drinks (fit, warp, leakage).

- Carbon intensity per lid (kg CO₂e) from supplier LCA data.

- Percentage of lids diverted to compost vs landfill vs recycling.

Conclusion: practical steps that create measurable change

The rise of paper cup lids in low-carbon coffee culture depends on measured choices: select materials supported by local end-of-life systems, prioritise suppliers with transparent certifications and high production efficiency, and design lids that reduce SKU complexity while meeting real service conditions. Combine these procurement and operational steps with clear customer messaging and local waste partnerships to turn product changes into verified emissions reductions.

+86-18863350588

+86-18863350588

English

English Français

Français Deutsch

Deutsch Español

Español